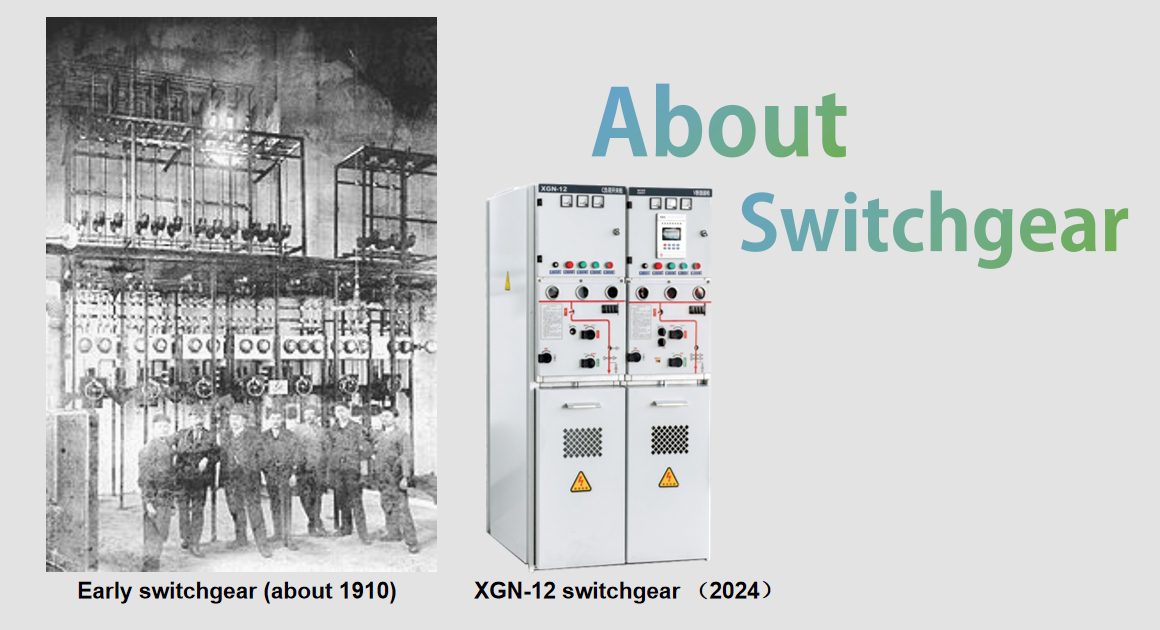

1. The Essence of Switchgear

Switchgear, in its simplest form, is a collection of electrical devices that work in harmony to control, protect, and isolate electrical equipment within a power system. It serves as the first line of defense against power surges, short circuits, and overloads, safeguarding the integrity of the entire electrical infrastructure.

1.1 Protection Against Electrical Perils

One of the most vital functions of switchgear is to shield electrical assets from potential disasters. When an electrical fault occurs, whether it’s a sudden spike in current or a short circuit, the switchgear springs into action. It contains components like circuit breakers and fuses that are designed to sense these anomalies and instantaneously interrupt the power flow. This not only prevents damage to expensive equipment such as transformers, generators, and motors but also significantly reduces the risk of electrical fires, ensuring the safety of both people and property.

1.2 Precision in Power Distribution

Imagine a bustling industrial complex with numerous machines running simultaneously, each requiring a specific amount of power. Switchgear acts as the master conductor, precisely regulating the distribution of electricity to these various loads. It ensures that each machine receives the right amount of power at the right time, maintaining a stable and efficient power supply. This is crucial for optimizing the performance of industrial processes, preventing equipment failures due to power fluctuations, and ultimately enhancing productivity.

1.3 Facilitating System Maintenance and Upgrades

In the ever-evolving world of technology, regular maintenance and upgrades of electrical systems are essential. Switchgear plays a pivotal role in this regard by allowing technicians to safely de-energize specific parts of the system. This means that maintenance tasks, such as equipment inspections, repairs, and replacements, can be carried out without the danger of electrical shock. Moreover, during system upgrades, switchgear enables the seamless integration of new components and technologies, ensuring that the power system remains up-to-date and reliable.

2. The Diverse Landscape of Switchgear Types

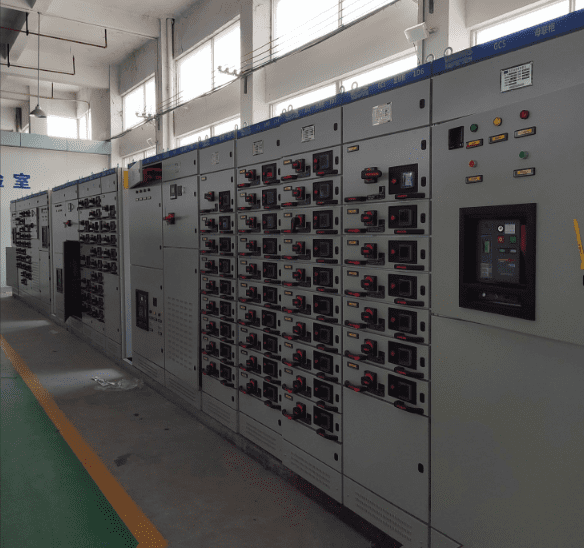

2.1 Low-Voltage Switchgear: The Backbone of Everyday Applications

Low-voltage switchgear, designed for systems operating at less than 1 kilovolt (kV), is the unsung hero of many industries. It finds extensive use in a wide range of applications, from healthcare facilities that rely on uninterrupted power for life-saving equipment to industrial buildings where it regulates the power supply to various manufacturing processes. This type of switchgear is equipped with an array of components, including low-voltage circuit breakers, earth leakage circuit breakers, and miniature circuit breakers. These components offer enhanced protection features such as arc-resistance and are often designed with space-saving in mind to meet the unique requirements of different installations. Whether it’s a small commercial establishment or a large industrial complex, low-voltage switchgear ensures the smooth and safe operation of electrical systems.

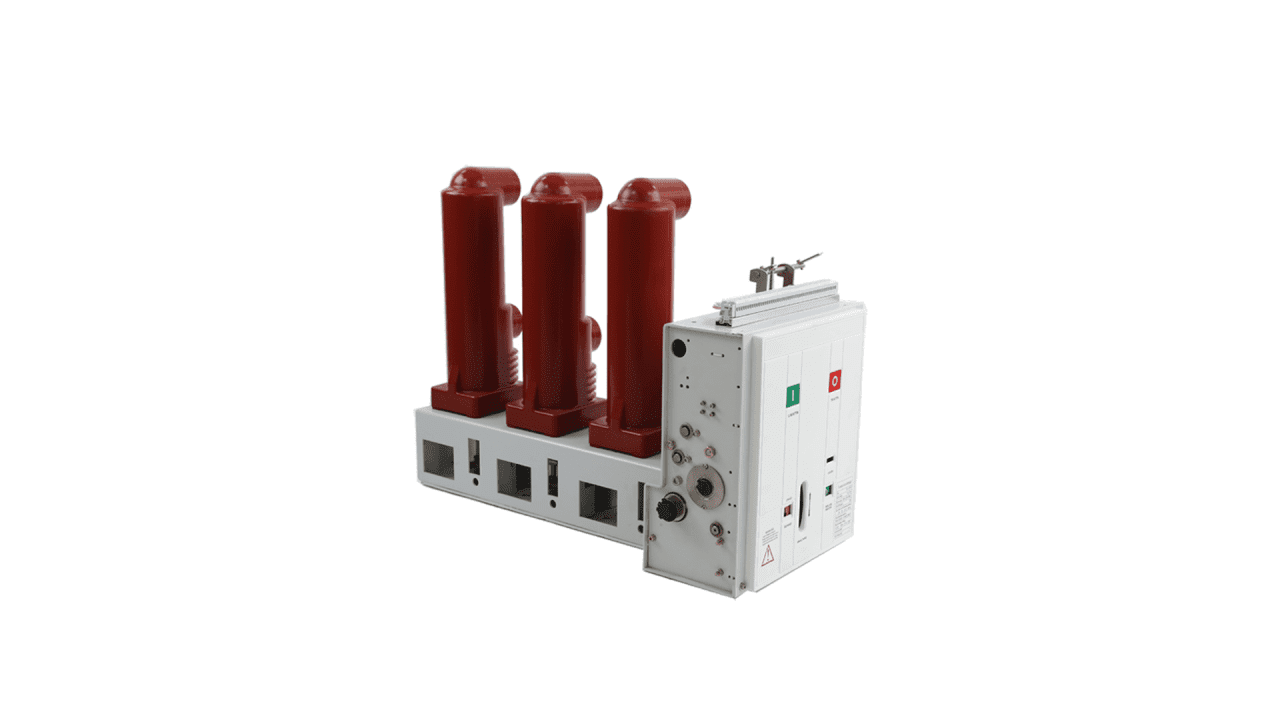

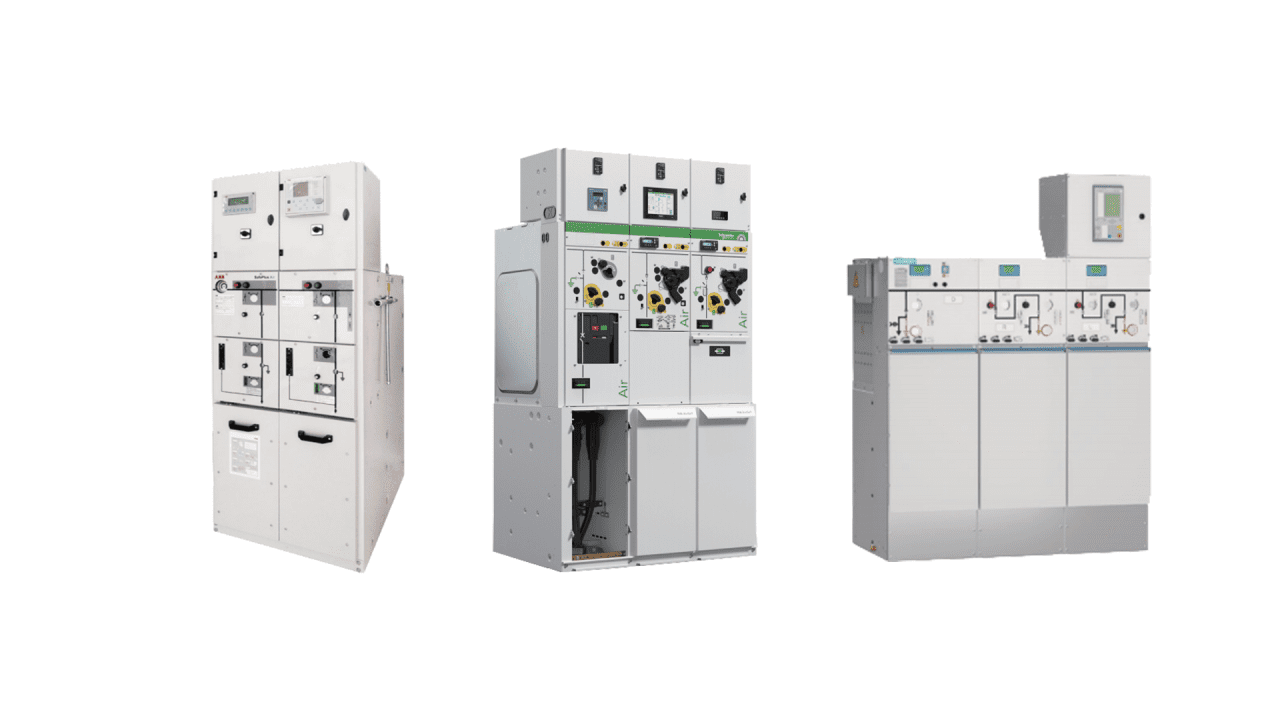

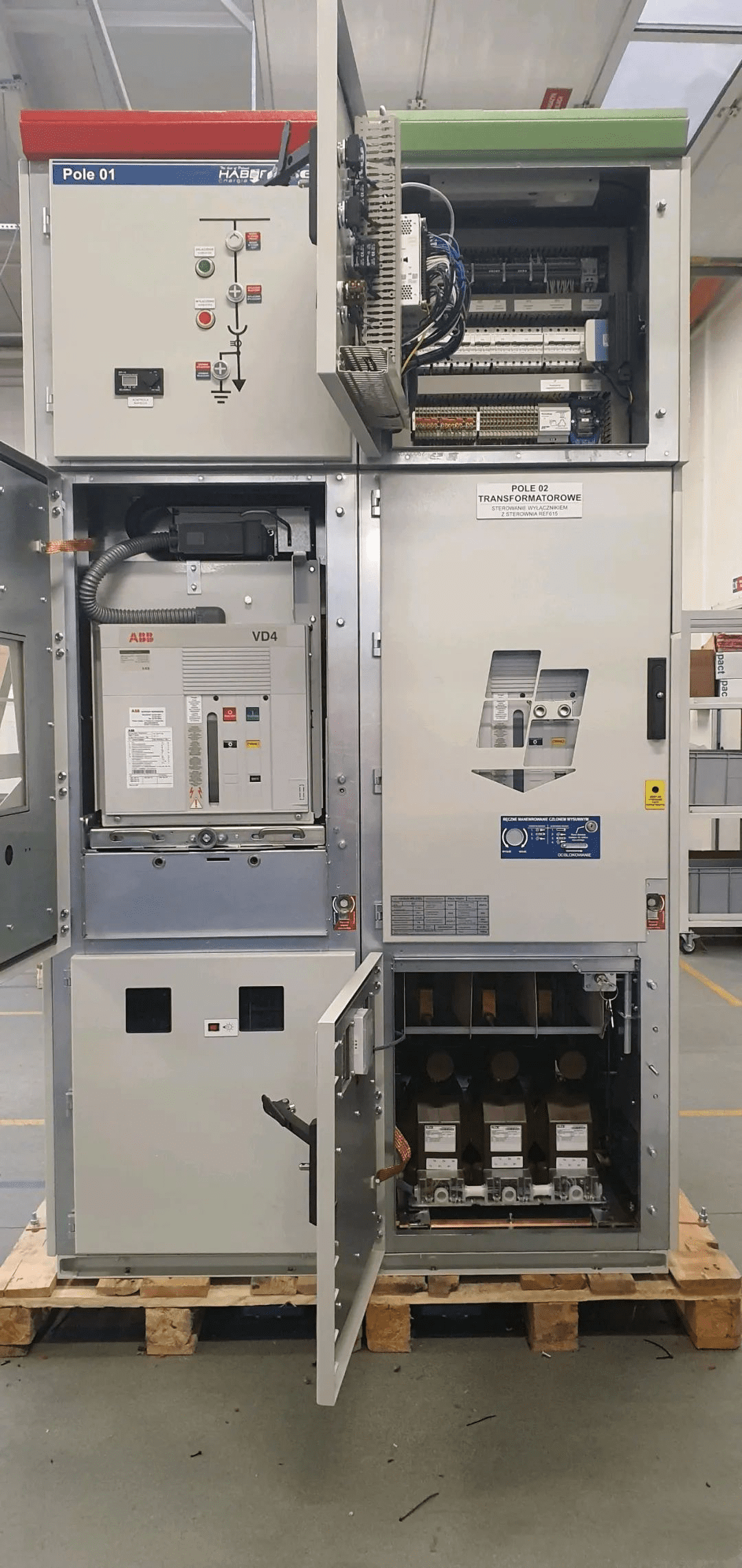

2.2 Medium-Voltage Switchgear: Powering Industrial Giants

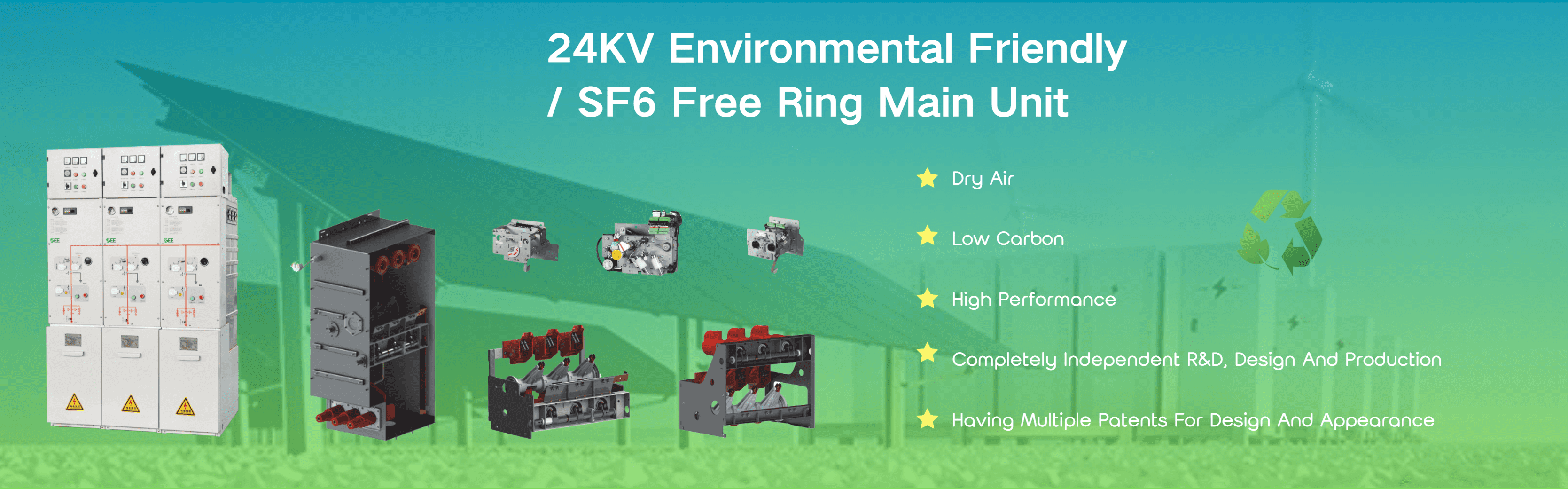

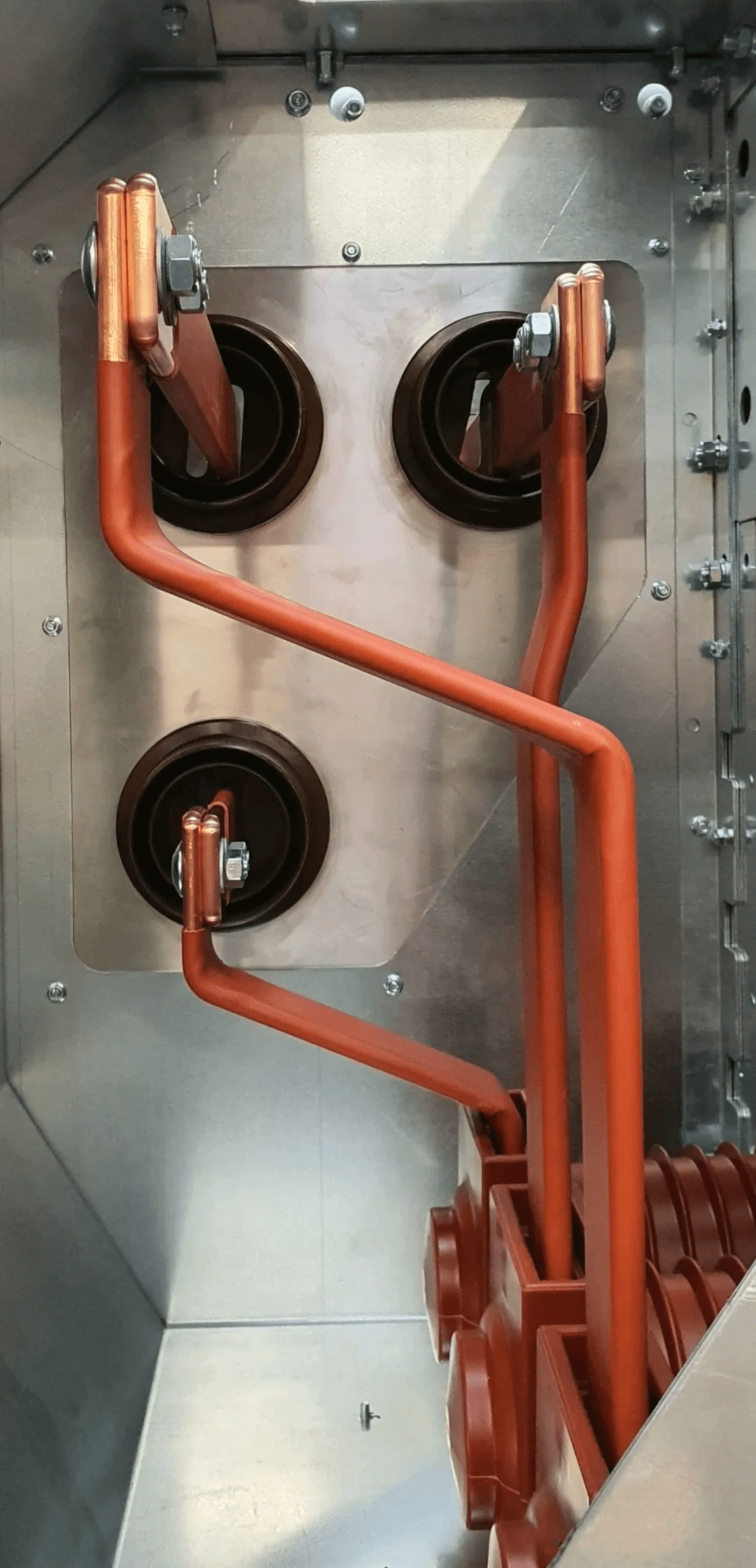

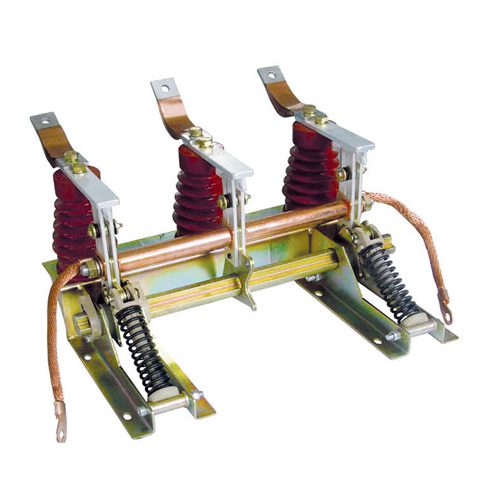

Medium-voltage switchgear, operating within the range of 1 kV to 35 kV (as per the corrected and more widely recognized range), is the powerhouse behind many industrial operations. It is specifically engineered to handle the high power demands of industrial setups, where large motors, generators, and complex production lines require a reliable and efficient power source. Medium-voltage switchgear employs advanced insulation technologies, such as gas-insulated (using gases like sulfur hexafluoride or its more environmentally friendly alternatives), air-insulated, and shielded solid insulators. These insulators not only protect the internal components from electrical faults but also provide effective cooling, ensuring the long-term reliability and performance of the equipment. From power generation plants to manufacturing facilities, medium-voltage switchgear is the driving force that keeps industries running smoothly.

2.3 High-Voltage Switchgear: The Linchpin of Transmission Networks

High-voltage switchgear, operating at voltages above 35 kV, is the cornerstone of large electric transmission and distribution systems. It is responsible for handling vast amounts of power over long distances, ensuring that electricity is efficiently transmitted from power plants to substations and ultimately to end-users. This type of switchgear is designed with a focus on reliability and safety, as any interruption in high-voltage power transmission can have far-reaching consequences. It incorporates components like high-current switching mechanisms, disconnectors, and earthing switches, which work together to control, regulate, and isolate power flow. High-voltage switchgear is commonly found in major power transmission corridors, substations serving large urban areas, and industrial complexes with high power consumption requirements.

3. The Inner Workings of Switchgear

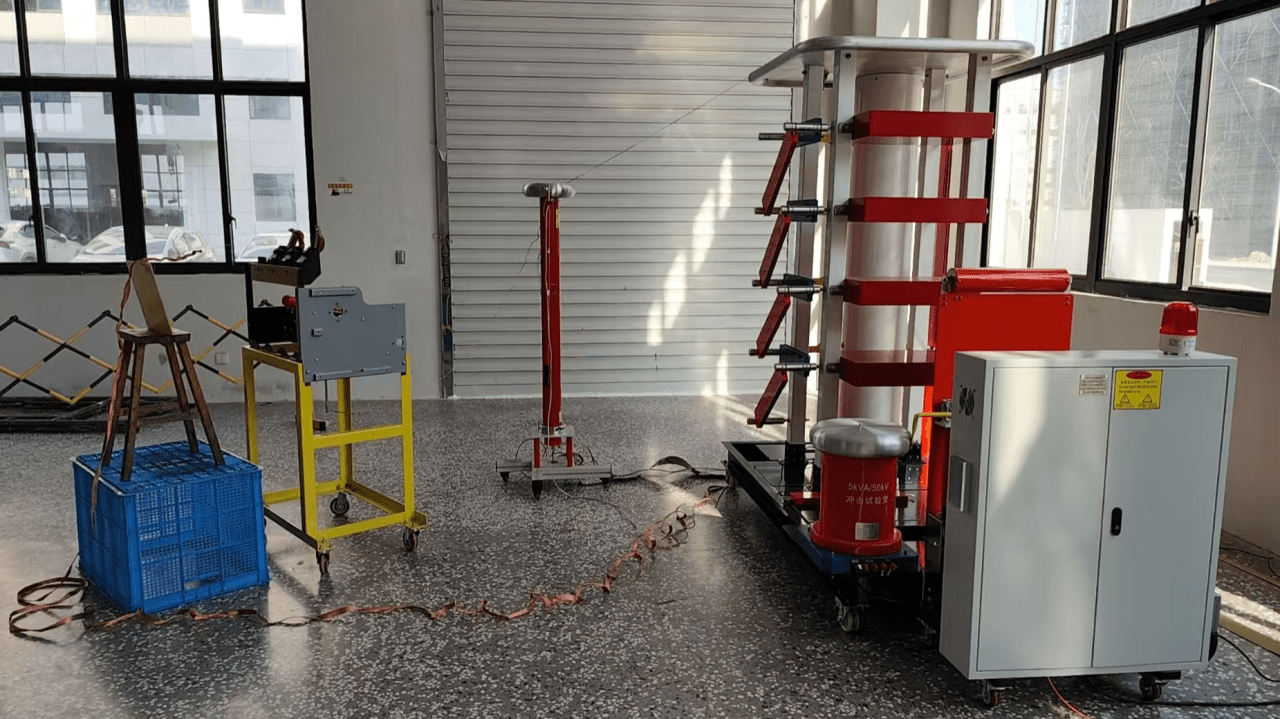

3.1 Detecting and Reacting to Faults: The Role of Relays and Circuit Breakers

At the heart of switchgear’s fault protection mechanism are relays and circuit breakers. When a fault occurs in the electrical system, relays act as the vigilant sensors, constantly monitoring the current and voltage levels. They are programmed to detect even the slightest deviations from normal operating conditions. Once a fault is detected, the relay sends a signal to the circuit breaker, which then swiftly interrupts the power flow. This process is not only rapid but also highly precise, ensuring that only the affected part of the circuit is isolated while the rest of the system continues to operate smoothly. The ability of switchgear to detect and respond to faults in milliseconds is crucial for minimizing downtime and preventing widespread power outages.

3.2 Power Flow Management: Balancing the Electrical Equation

Switchgear is not just about protection; it also plays a crucial role in optimizing power flow. In a complex electrical network with multiple power sources and loads, switchgear acts as the intelligent traffic controller. It continuously monitors the power demand and availability, making split-second decisions to ensure that power is distributed evenly and efficiently. For example, in a situation where one power source fails, switchgear can seamlessly switch to an alternative source, ensuring uninterrupted power supply to critical loads. This dynamic power flow management is essential for maintaining the stability and reliability of the entire electrical system, especially in applications where downtime is not an option, such as data centers and hospitals.

3.3 Isolation for Safety and Maintenance: A Shield Against Electrical Hazards

Safety is of paramount importance in any electrical installation, and switchgear provides the necessary isolation for maintenance and repair work. When technicians need to work on a particular piece of equipment or a section of the electrical system, they can rely on switchgear to completely de-energize the relevant part. This isolation creates a safe working environment, free from the risk of electrical shock. Additionally, during routine inspections and maintenance, switchgear allows for individual components to be isolated and tested, ensuring that any potential issues are detected and resolved before they escalate into major problems.

4. Switchgear in the Global Context: Adapting to Different Standards

4.1 International Standards and Their Influence

The world of switchgear is governed by various international standards, with the International Electrotechnical Commission (IEC) standards being widely recognized. The IEC provides a common framework for the design, testing, and installation of switchgear, ensuring compatibility and interoperability across different countries and regions. These standards not only promote safety and reliability but also facilitate global trade in electrical equipment. For example, a switchgear manufacturer that adheres to IEC standards can market its products more easily in multiple countries, knowing that they meet the basic requirements for quality and performance.

4.2 Regional Variations and Their Significance

On a global scale, while international standards provide a fundamental framework for the design, testing, and installation of switchgear, different regions and countries formulate specific requirements and standards based on their own circumstances, and these differences hold significant importance in practical applications.

The International Electrotechnical Commission (IEC) standards are widely referenced globally. They stipulate common technical guidelines for switchgear, promoting the compatibility and interoperability of equipment across different countries and regions, and facilitating international trade in electrical equipment.

In the United States

The standards developed by the American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE) are adapted to the characteristics of the US power grid and industrial applications. For example, in the definition of the voltage range of medium-voltage switchgear, there are certain differences compared to the IEC standards. The medium-voltage range specified in the US standards is more in line with the grid structure and industrial power demand in the US in certain application scenarios, forming a system with local characteristics in equipment selection, system design, and operation and maintenance.

In Europe

In addition to following the IEC standards, each country also formulates additional regulations and standards based on local environmental conditions, grid infrastructure, and safety requirements. For instance, some European countries have stricter requirements for the environmental performance of switchgear, driving innovation in the selection of insulating materials and energy-efficient design of equipment to ensure the stable and safe operation of equipment in the complex and diverse power environments in the region.

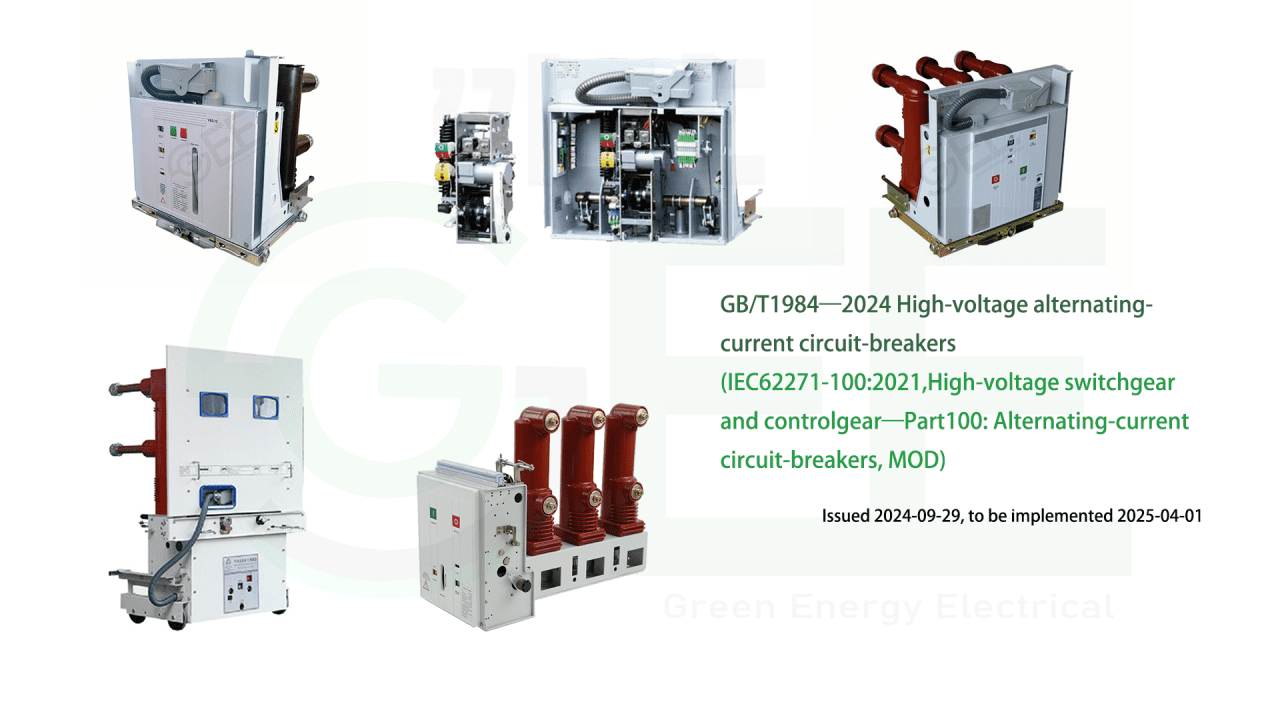

In China

The national standards (GB) specify in detail the various performance indicators, technical parameters, and safety norms of switchgear. The GB standards fully consider the scale, structure of the Chinese power system, and environmental differences in different regions in aspects such as voltage level division, insulation level requirements, and protection level settings. For example, the definition and application range of medium-voltage switchgear are clearly defined, enabling it to better meet the diverse demands of domestic power infrastructure construction, industrial production, and urban power supply, effectively ensuring the stable and reliable operation of the power system. At the same time, it also promotes the standardization and normalization of the domestic switchgear manufacturing industry.

In Saudi Arabia

The SDMS specifications formulated by the Saudi Electricity Company (SEC) target the special environment and power demands in the Saudi region. The harsh environmental conditions such as high temperature and sandstorms in Saudi Arabia pose higher challenges to the performance and reliability of switchgear. The SDMS specifications have strict requirements in terms of the heat resistance, sand and dust resistance, protection measures, and long-term operation stability of the equipment, ensuring that the switchgear can operate normally under the severe environment in Saudi Arabia. It provides continuous and stable power support for the local petrochemical and energy industries, and also provides clear technical guidance for enterprises engaged in power engineering construction and equipment supply in Saudi Arabia.

4.3 The Future of Switchgear: Trends and Innovations on the Horizon