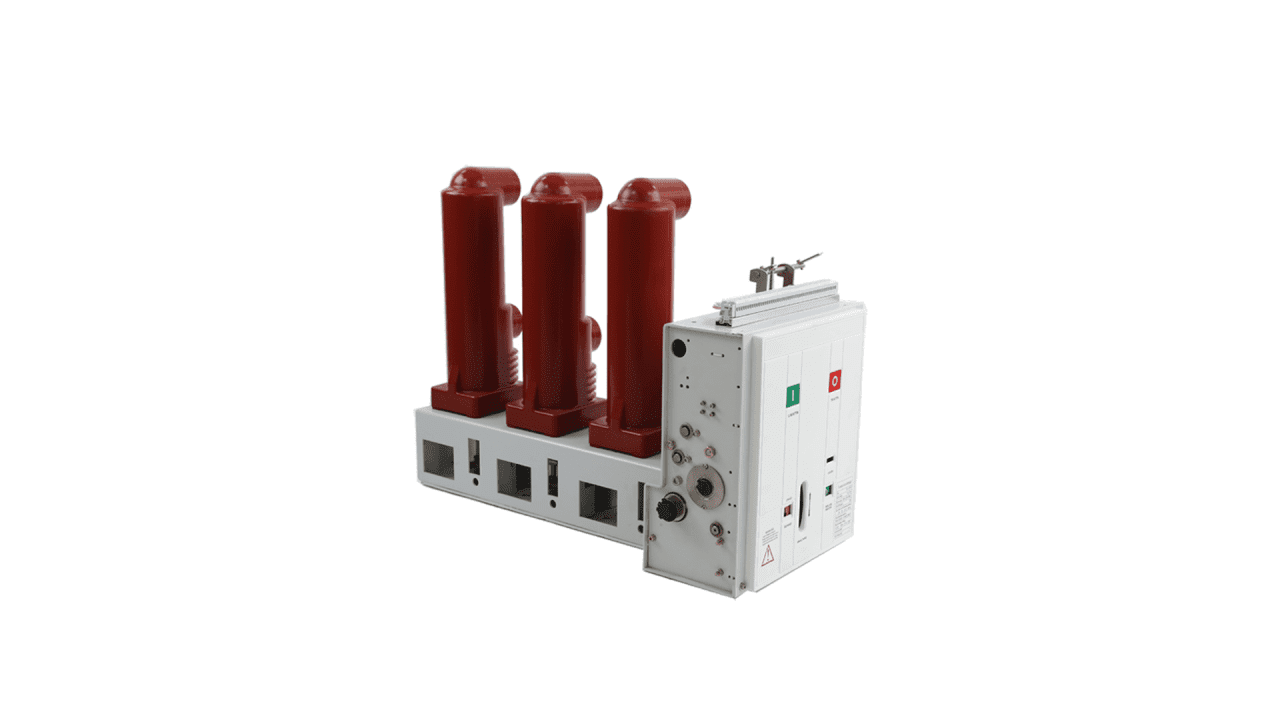

Vacuum circuit breakers have several advantages, including high interrupting capability, excellent arc-extinguishing performance, long mechanical and electrical life, low maintenance workload, and extended maintenance intervals. Therefore, vacuum switches are widely recognized by users.

The vacuum degree of the vacuum interrupters is a crucial technical indicator that ensures the insulation and arc-extinguishing performance of the switch. The vacuum degree testing of circuit breakers has become an essential part of regular inspections and preventive testing.

This article introduces several methods for detecting the vacuum degree. It analyzes the reasons for the reduction in vacuum degree in the Vacuum Interrupters and presents a method for testing vacuum switches using vacuum degree testers.

Strengthening the detection of the vacuum degree in the Vacuum Interrupters is vital, as they are the core components of the vacuum switch.

Common Methods for Checking Vacuum Degree

Observation Method

This method allows operators to make a simple judgment about the operating vacuum circuit breaker. By observing the color changes of the getter film on the surface of the vacuum glass envelope, operators can determine changes in vacuum degree. When the vacuum is good, the getter film appears mirror-like; if the vacuum decreases, the film turns milky white. This method can only detect low vacuum levels and is not applicable for ceramic-insulated interrupters.

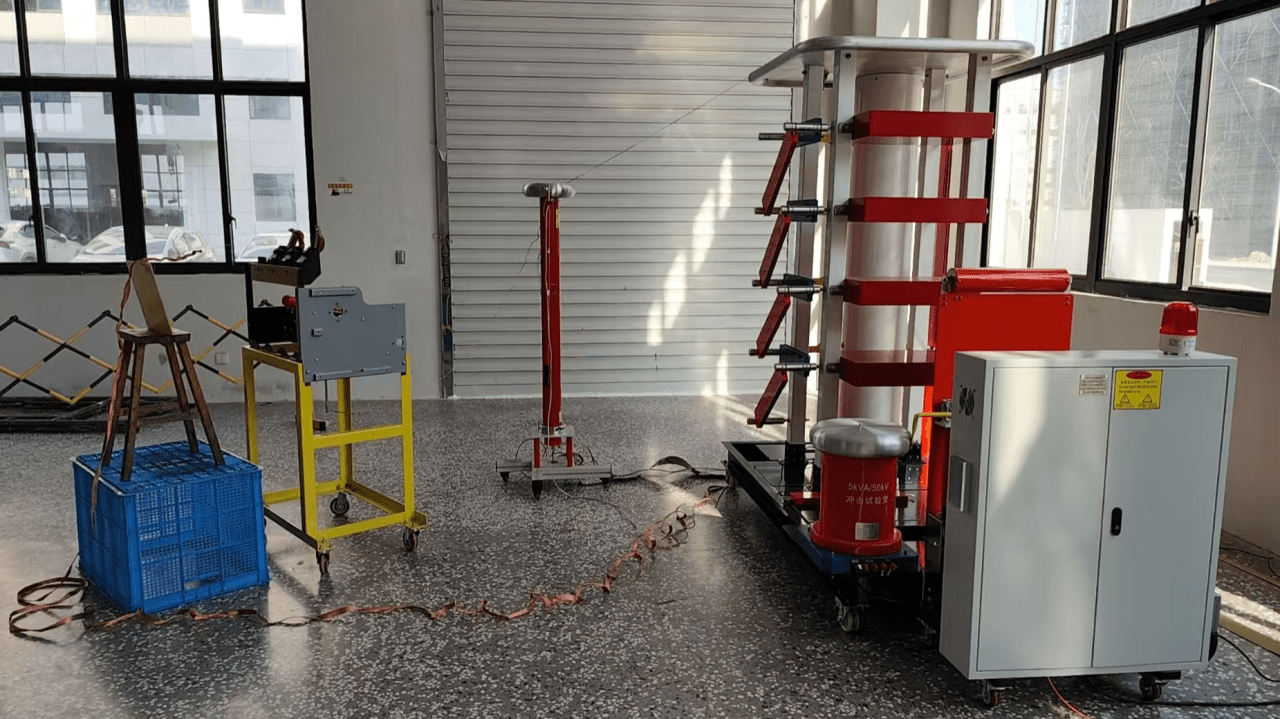

AC Voltage Withstand Method

The vacuum degree of the interrupters is detected using a power frequency withstand voltage test. The vacuum switch is placed in the off position, and an AC voltage is applied between the moving and stationary contacts of the interrupters. The withstand voltage test standard requires applying 70% of the rated power frequency withstand voltage at the rated opening distance for 1 minute, then increasing to the rated withstand voltage within 1 minute, maintaining it for another minute. The test is deemed qualified if there are no sudden needle movements or tripping phenomena on the measuring instrument. Minor sparks or slight luminous phenomena are permissible inside the chamber.

Electromagnetic Method

The electromagnetic method tests the vacuum interrupters. The testing procedure involves applying a magnetic field between the separating contacts of the interrupters, followed by a pulsed voltage of significant duration (100 ms). The magnitude of this pulse can be controlled by the current flowing through it, allowing for the estimation of gas pressure in the interrupters. Based on current field test conditions, this method provides the most accurate and effective data, allowing precise calculation of the vacuum degree in the vacuum switch, with high testing reliability.

In addition to these three primary methods, there is also the Spark Gauge Method, which is suitable only for glass-tube vacuum interrupters. A spark gauge leak detector assesses the color of light within the vacuum tube as it moves over the surface of the interrupters. A light cyan color indicates a good vacuum, while red and blue indicate a significantly low vacuum. No illumination suggests severe leakage.