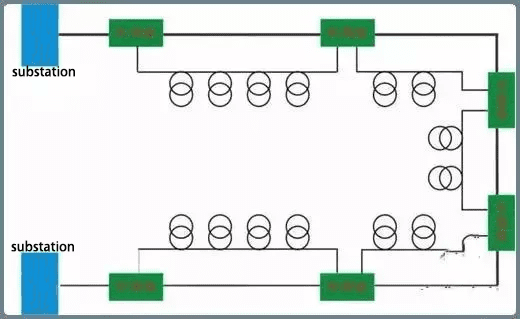

In today’s power distribution field, the Ring Main Unit (RMU) plays a crucial role. It is a factory-assembled metal-enclosed switchgear widely used in the power supply systems of various infrastructures, including high-rise buildings, industrial facilities, and residential communities. A deep understanding of the RMU is of great significance for optimizing power distribution decisions.

1. Definition and Basic Composition of the Ring Main Unit

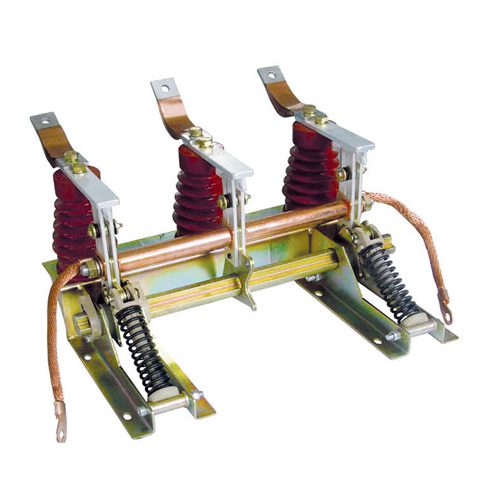

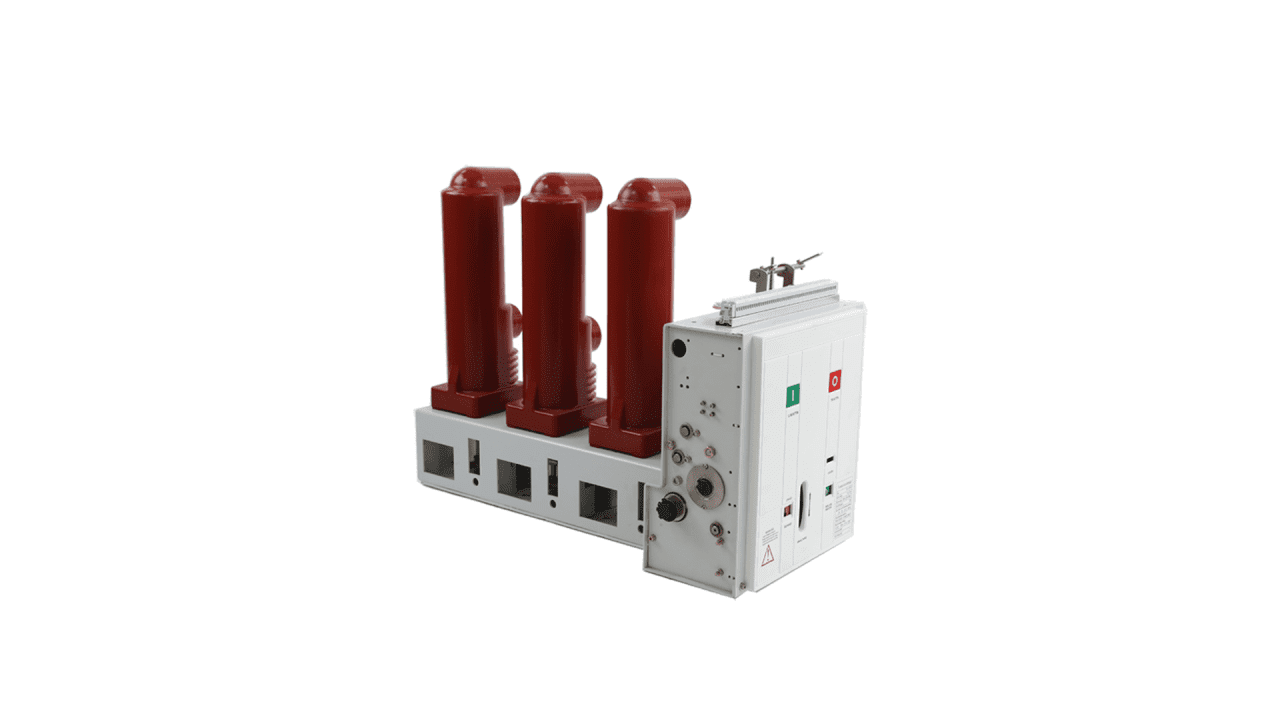

The RMU is located at the load connection point of the ring distribution network. Its internal main components include switches that connect the load to the main conductor, as well as fuses or circuit breakers for distributing medium and low voltage power. This compact design enables it to maintain a stable power supply even in harsh environments, and it can quickly switch power sources during maintenance or emergencies, reducing downtime.

2. Development History of the Ring Main Unit

As a pioneer in the power industry, Europe put forward higher requirements for the structure and equipment of the power supply network during the construction of urban power grids. The concept of the ring power supply network emerged, promoting the birth of the RMU. Electrical giants such as Siemens, with their advanced technology, continuously improved and innovated, enabling the RMU to play an important role in the 10kV and below urban medium and low voltage distribution networks, effectively solving problems such as power source switching, load distribution, and short-circuit protection.

3. Working Principle of the Ring Main Unit

Based on the closed-loop ring system operation, even if a component in the system fails, the power supply will not be affected, and the power can be rerouted from other paths to ensure the reliability of the circuit. Its core components such as switches, circuit breakers, and fuses can handle electrical faults with high precision, protecting the system from overload and short-circuit. The compact design saves space and is suitable for installation in areas with limited space. It integrates multiple devices inside, simplifies the electrical management system, and saves installation time and labor costs. At the same time, its good environmental insulation performance can resist contaminants such as dust and moisture, extending the service life of the equipment.

4. Advantages and Disadvantages of the Ring Main Unit

- Advantages

- High reliability: The combination of load switches and fuses enables the fuse to quickly cut off faults in case of short circuits, with better protection effect.

- Small size and simple structure: It occupies less space and is suitable for places with limited space.

- Low operation and maintenance workload: The operating mechanism is simple, with fewer parts, resulting in low operation and maintenance costs.

- Low cost: It has high cost performance and is widely used in medium and low voltage distribution networks.

- Disadvantages

- Limited protection function: The protection selectivity and sensitivity for complex faults are not as good as those of circuit breakers.

- Small rated current: It is limited when connecting large-capacity transformers or loads.

- Weak expansion ability: The internal structure is fixed, and it is difficult to expand.

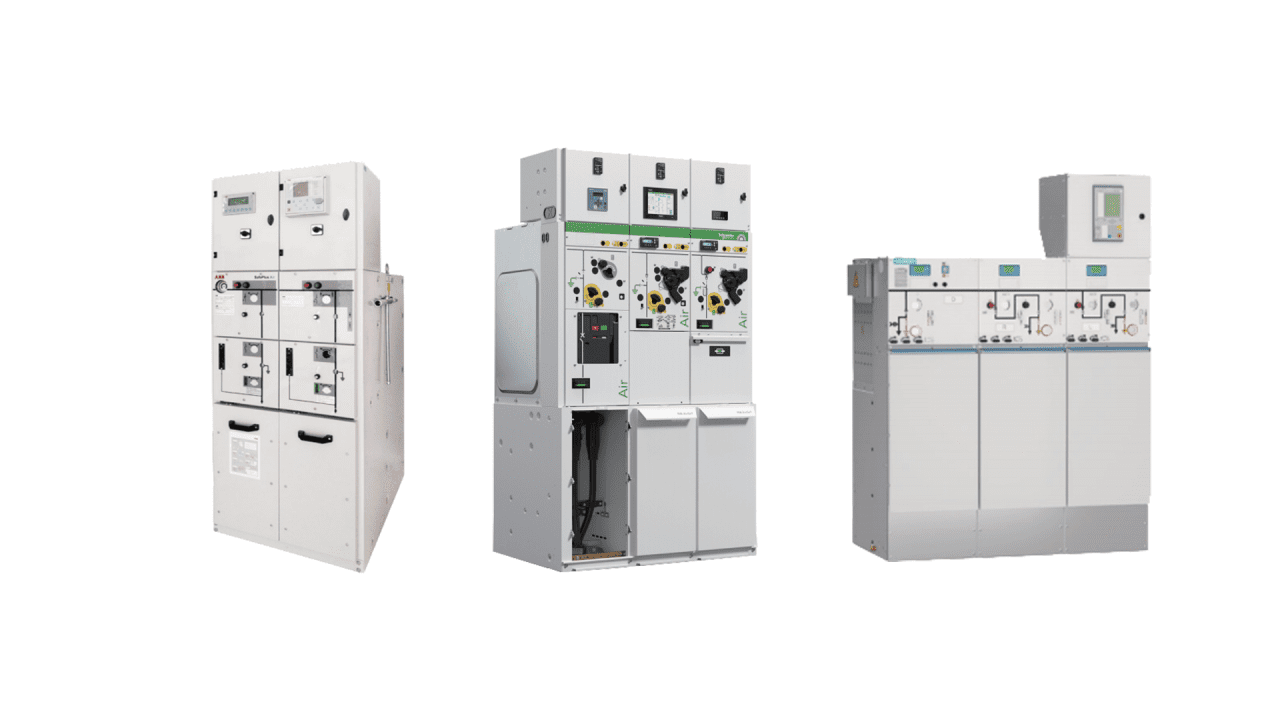

5. Structure and Insulation Classification of the Ring Main Unit

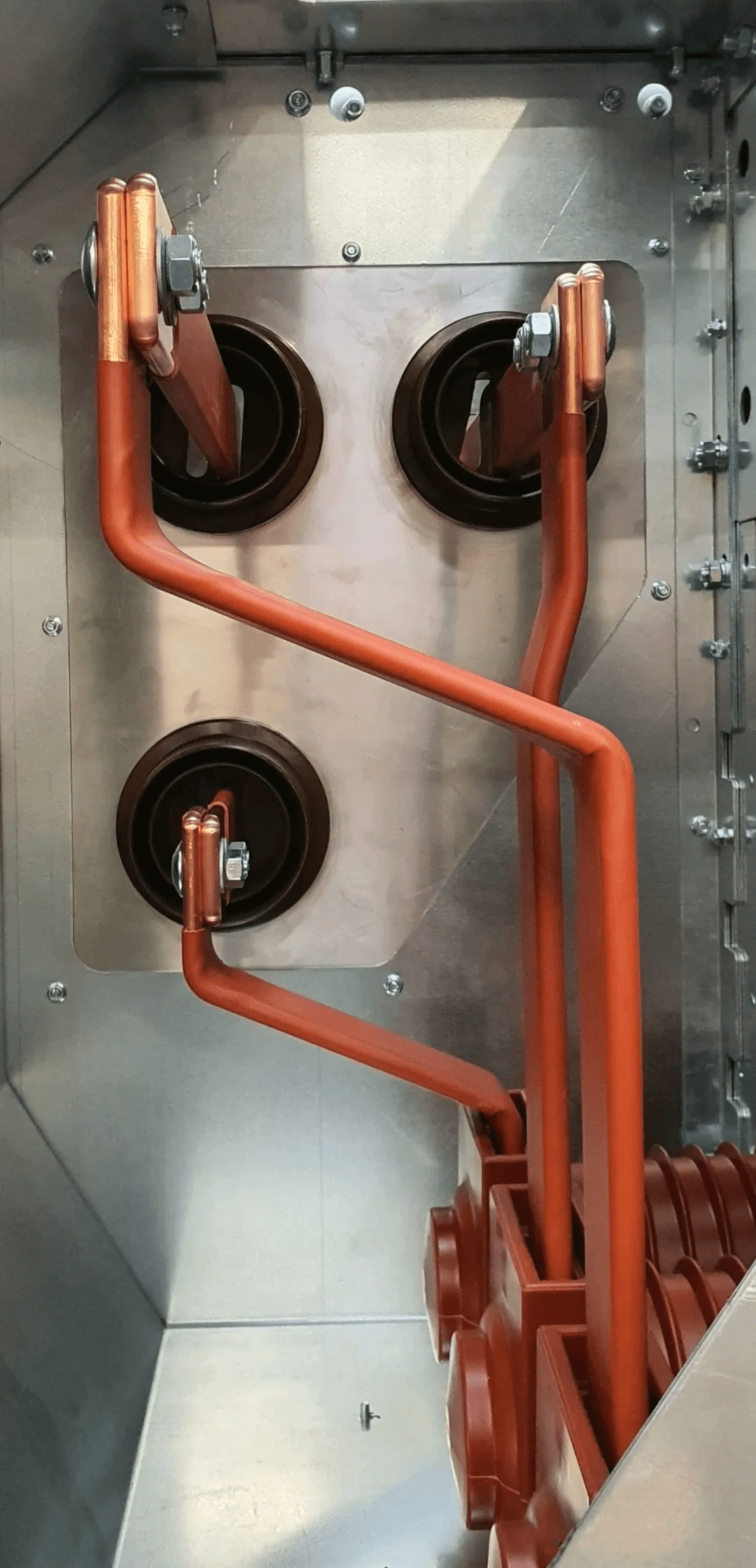

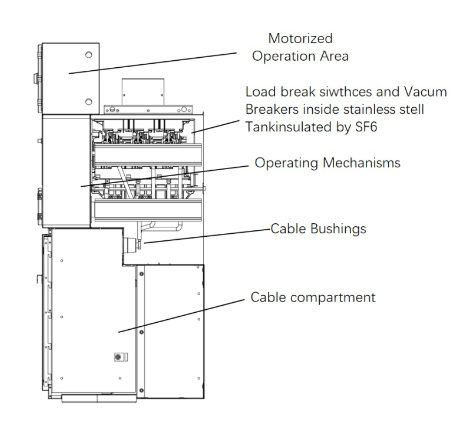

- Internal Components

- Input and output cable compartments: Connect to the transformer.

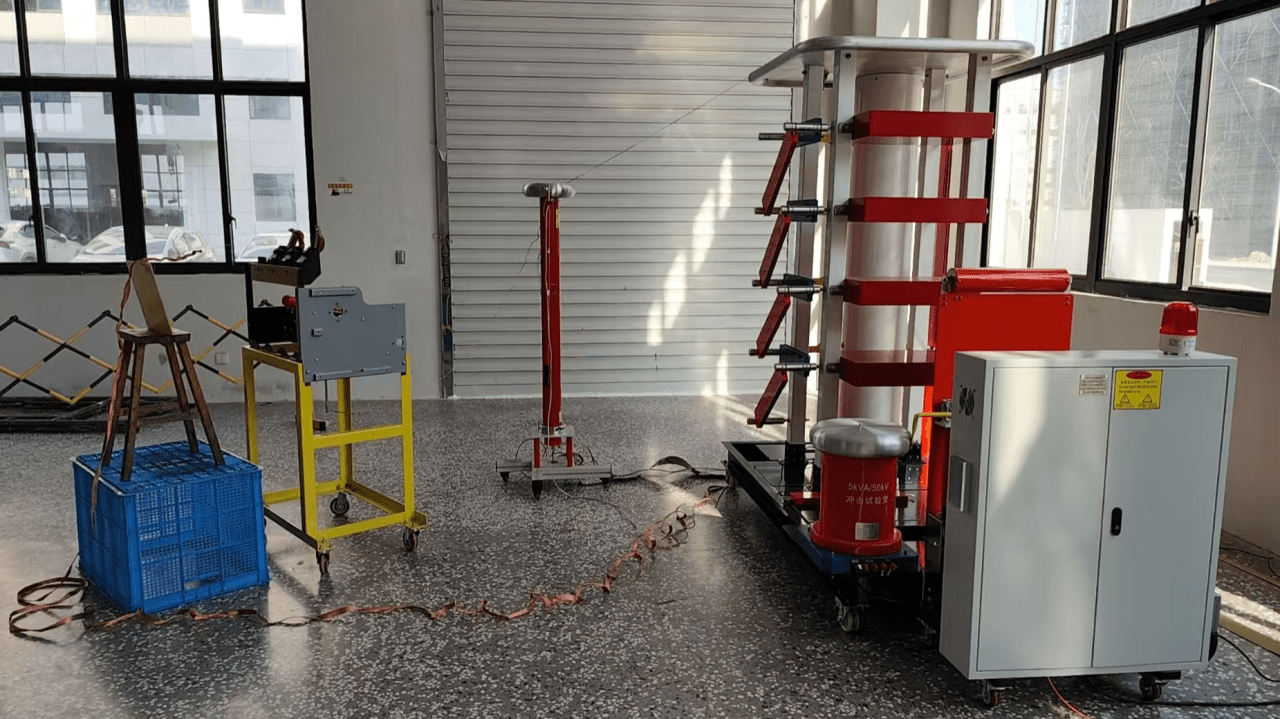

- Switchgear: Some are installed in SF6 gas tanks with good environmental tolerance.

- Customizable compartments: Can be configured with different numbers of compartments according to needs.

- Insulation Classification

- Air-insulated cabinet: Suitable for environments with low humidity and dust.

- Vacuum-insulated cabinet: It has good insulation performance in a vacuum environment.

- SF6 gas-insulated cabinet: It has strong resistance to environmental factors, but SF6 is a greenhouse gas, and its use requires strict handling and recycling.

- Environmentally friendly gas-insulated cabinet: It meets environmental requirements and is filled with environmentally friendly gas.

6. Common Voltage Levels of the Ring Main Unit

- 10kV: Commonly used in distribution stations of urban residential communities and general factory enterprises.

- 12kV: Widely used in medium voltage distribution systems, such as distribution rooms of small factories and commercial buildings.

- 24kV: Used in industrial areas and large commercial complexes with high requirements for power supply capacity and reliability.

- 35kV: Suitable for high-voltage distribution scenarios such as large industrial and mining enterprises and substations.

- 40.5kV: Used in industrial production or large power transmission hubs with high voltage requirements.

7. Frequently Asked Questions about the Ring Main Unit

- It is widely applicable in various fields, including indoor and outdoor, industrial and urban scenarios.

- The ring system ensures that the power supply is not interrupted when part of the system fails, enhancing the reliability of power distribution.

- The designed service life exceeds 20 years, and regular maintenance can extend the life.

- It is designed to be low maintenance. The robust structure and reliable performance reduce maintenance costs.

- It can be customized according to special needs, including voltage, installation method, compartment configuration, and insulation type.

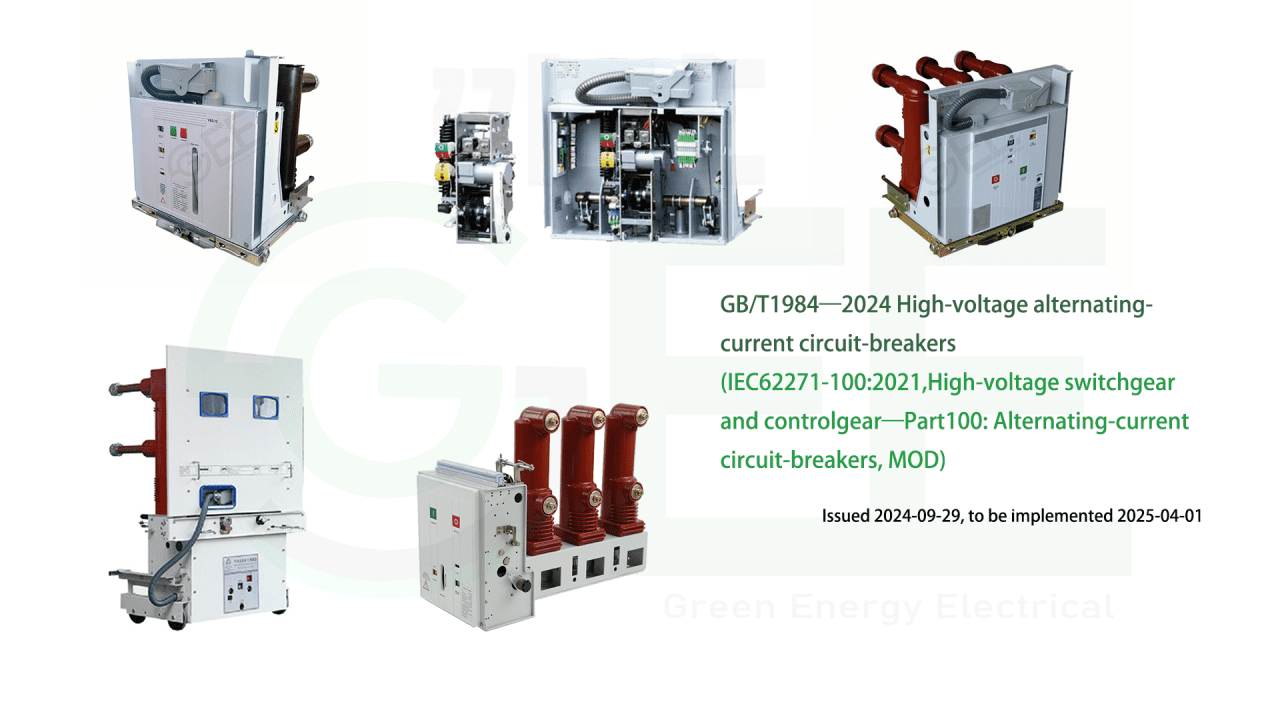

8. Importance and Selection of the Ring Main Unit

In modern power distribution systems, the RMU is compact in design, efficient in operation, and multifunctional, and is crucial for ensuring the reliability of power supply. When choosing, consider high-quality manufacturers. Their high-tech capabilities and customization capabilities can ensure that the products meet standards and operate stably for a long time. Understanding the working principle, advantages, and types of the RMU is helpful for solving power distribution problems and meeting power needs. For more information, please contact Green Energy Electrical Industry Co., Ltd for relevant consultations and materials.