Description

Products Introduction

- High-quality Materials and Exquisite Craftsmanship:

- The gas tank is made of a high-quality 3-mm-thick stainless steel shell. The stainless steel plate is precisely cut by laser and then automatically welded by advanced welding robots. This combination of processes comprehensively ensures the airtightness of the gas tank, making gas storage safer and more stable and greatly reducing the risk of gas leakage, which meets the high standards requirements of industrial equipment.

- Gas Treatment and Synchronous Detection:

- The SF6 gas filled in the tank is synchronously carried out with vacuum leakage detection. It closely monitors the gas state, controls the airtightness of the gas tank in real time, and promptly detects potential leakage hazards, effectively ensuring the continuous and stable operation of the equipment. It is a key link in ensuring the safety of the power system.

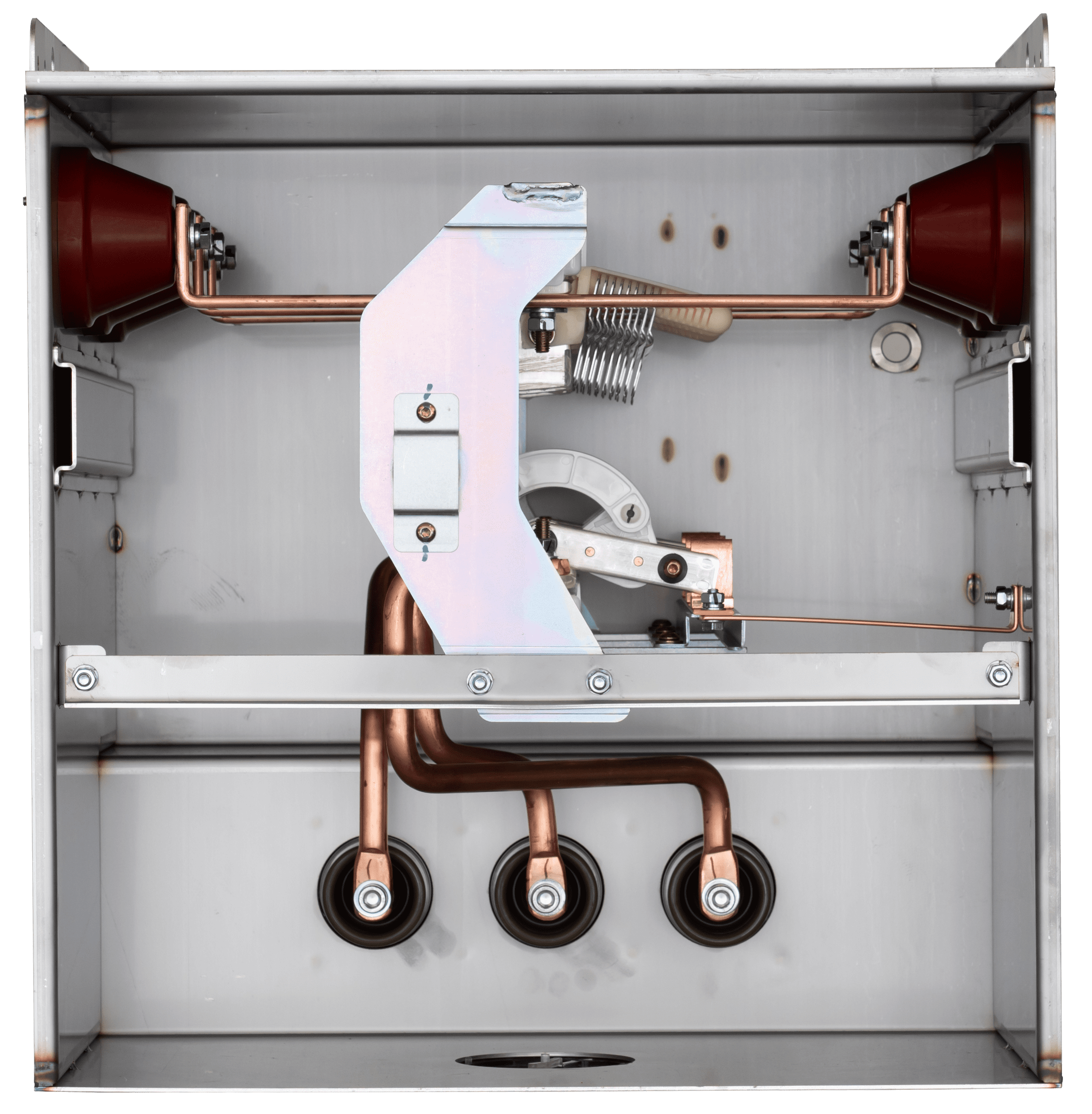

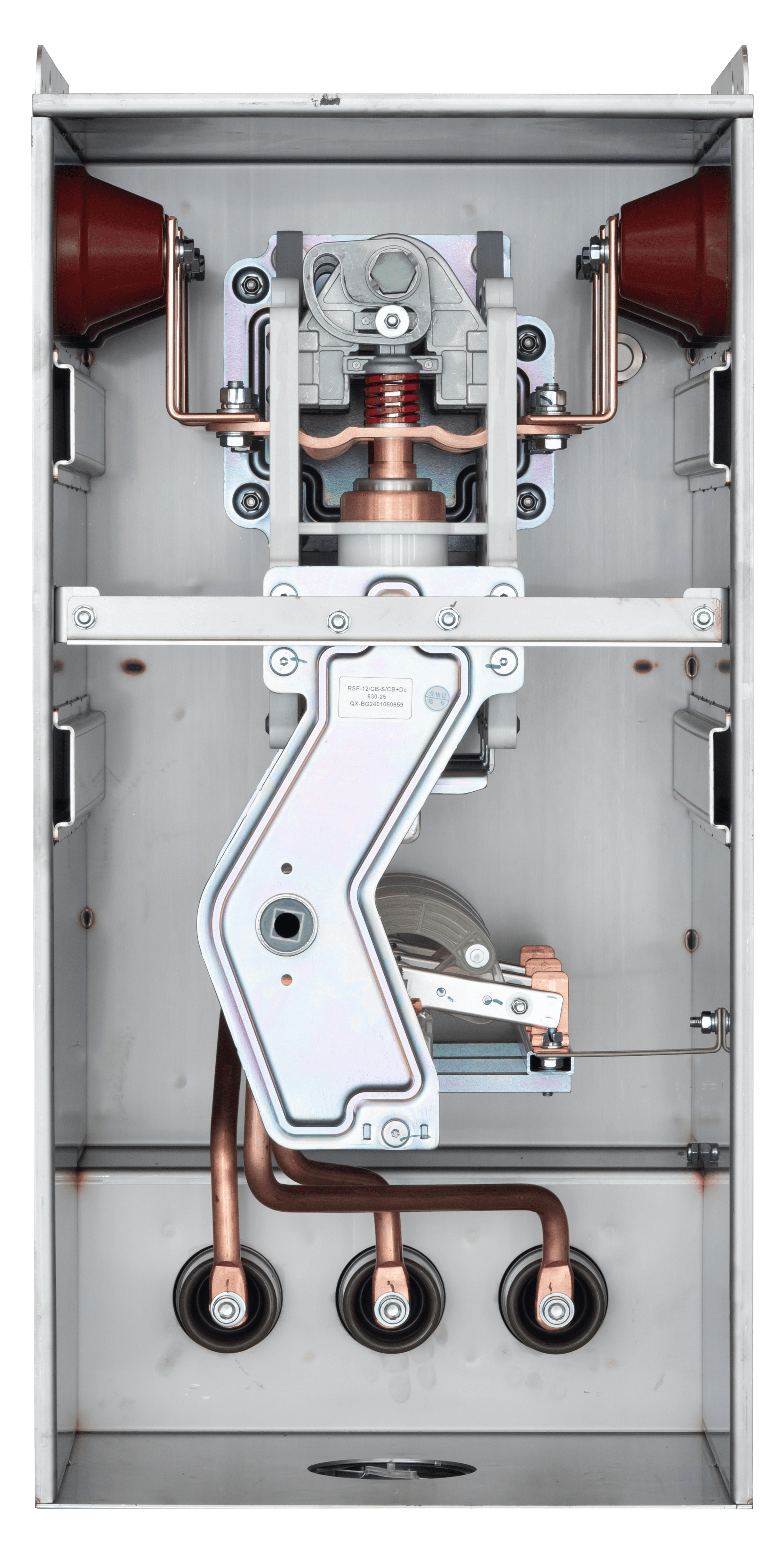

- Sealing Protection and Strong Resistance:

- Key switch moving parts such as load switches, earthing switches, fuse insulator cylinders, and busbars are all sealed inside the stainless steel gas tank. The protection level of the inflatable shell reaches IP67, which means that it is completely unaffected by common environmental factors. Whether it is in a humid environment prone to condensation, under the attack of cold frost, in a salt foggy environment, in the face of dust and dirt accumulation, in a highly corrosive scene, or under long-term ultraviolet irradiation and chemical substance erosion, it can effectively resist and stably and reliably maintain the performance of the equipment and extend its service life.