The latest version of GB/T 5273-2016 (which replaces GB/T 5273-1985) is based on IEC 62271-301:2009. In terms of form and dimensions, it has removed the specification of terminal shapes and sizes, as well as deleted Appendix A (which provided recommended terminal dimensions based on rated current and their connection methods) and Appendix B (which listed recommended torque values for electrical connections of terminals). This means that busbar joints no longer require full contact overlap—i.e., the overlap length no longer needs to match the width. Manufacturers may determine the busbar overlap length, the number of bolts, and the bolt tightening torque according to product design.

For busbars, one can rely on experience or certain calculations to determine the current density, and based on this, select the appropriate copper bar specifications.

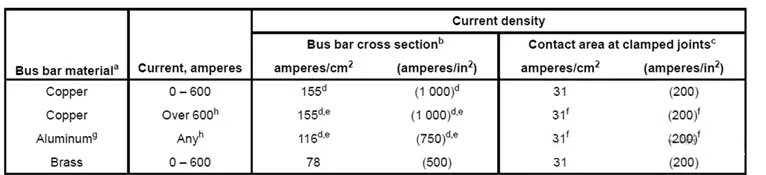

As for current density at the overlapping section, North American low-voltage switchgear standards provide specific limits:

For copper conductors with current below 3000 A: not more than 1.55 A/mm²

For aluminum conductors at any current rating: not more than 1.16 A/mm²

For brass conductors with current up to 600 A: not more than 0.78 A/mm²

For example, using copper conductors for 3000 A, the required cross-sectional area is:

3000 / 1.55 = 1935.48 mm²

Thus, the cross-section must not be less than 1935.48 mm², and two 100 × 10 mm copper bars can be used, with a total area of 2000 mm².

If aluminum conductors are used, the required area is:

3000 / 1.16 = 2586.20 mm²

Hence, two 120 × 12 mm aluminum bars (1440 mm² each) would be needed.

Notes to the Table:

a – Multiple busbars connected in parallel must use the same material.

c – When determining the contact surface area of bolted or riveted joints, do not deduct the area of holes for bolts or rivets, nor add the area of bolts, washers, or rivets.

f – Joints must be bolted and plated with either silver or tin.

g – The minimum electrical conductivity should be 55% IACS (International Annealed Copper Standard).

h – In Canada, the maximum current is limited to 3000 A.

According to the table, the maximum current density for the overlapping section, regardless of copper, aluminum, or brass, must not exceed 0.31 A/mm². Footnote c confirms that bolt hole areas are included in the total contact area.

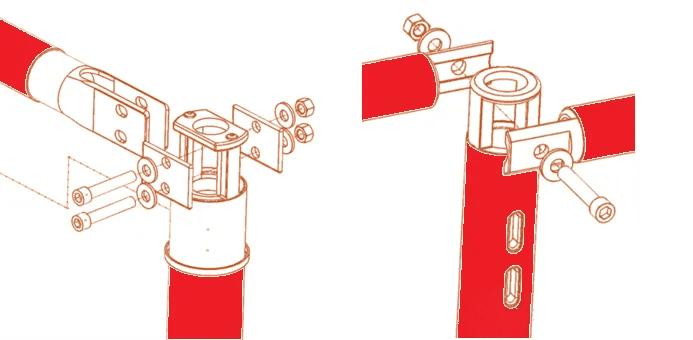

This requirement is quite strict. For instance, with a single copper bar joint rated for 1200 A:

1200 / 0.31 = 3870.97 mm²

If using a single 80 × 10 mm copper bar, then:

3871 / 80 = 48.39 mm,

This means full-face contact (e.g., 80 × 80 mm) is not required, but the overlap length must exceed 48 mm.

Hence, the common practice of left-right half overlap of about 40 mm on each side in switchgear would not meet this standard.

If multiple copper bars are used, the required overlapping area must be multiplied by the number of contact surfaces.

For example, in a 3000 A switchgear:

3000 / 0.31 = 9677.42 mm²

With two 100 × 10 mm copper bars, there are three contact surfaces, so:

9678 / 3 = 3226 mm²,

3226 / 100 = 32.26 mm

Using a 48 mm overlap per bar results in:

48 × 100 × 3 = 14,400 mm²,

which far exceeds the requirement, and fully meets the standard.

It is important to note that the above specifications come from ANSI (American) low-voltage switchgear standards, and are applicable only to products that have not undergone or passed temperature-rise testing. If a switchgear unit passes the temperature-rise test, then the above limits do not apply.

In practice, current density at the connection point does not fully reflect temperature rise. Increased pressure can reduce contact resistance and therefore lower heating. Other factors such as thermal conductivity and heat dissipation conditions also play a role, which must be verified through testing. The joint must also meet the requirements for electrodynamic and thermal stability. Thus, no single standard or technical specification should be used as the sole reference. A comprehensive system-level simulation and analysis is necessary to develop innovative and sustainable solutions that optimize performance and conserve resources.