Many people think that the earthing switch is just a simple earthing device. As long as it can be closed and the ground connection can be maintained, it is fine. Therefore, the earthing switch is not taken seriously. The contacts, springs, etc., are made of simple and cheap materials, and the manufacturer does not pay attention to the performance and quality of the earthing switch. Also, it can be used, closed, and separated, it is good, and the operation is labor-saving.

In fact, the function of the earthing switch is to ensure the safety of personnel during the maintenance and inspection of electrical equipment. For equipment with a voltage level of 10,000 volts, 35,000 volts, and higher, it must be reliably earthed before it can be repaired.

Hanging the earthing wire is one method, but the earthing switch is by no means as simple as simply connecting the main circuit to the earth.

Using an earthing switch is a safer and more reliable method. Whether it is a load device, a wire, or a cable, even if the circuit is disconnected, a certain amount of electricity will be stored. The capacitance of a long cable to the ground, the inductance and capacitance circuit in the equipment, etc., these accumulated and stored electricity will take a long time to consume. If the maintenance personnel touch it before release, it will form a circuit with the earth, thereby releasing electrical energy through the human body, causing electric shock injuries to personnel.

It is very important to release the residual charge in the line through an earthing switch with closing ability.

The role of the earthing switch in the power system

– Cause artificial earthing to meet the protection requirements. Ensure that there is an obvious mechanical earthing point in the circuit, determine that there is no residual pressure in the line, and ensure the safety of maintenance and line shutdown.

– Replace the portable ground wire to ground the equipment during the maintenance of high-voltage equipment and lines to protect safety.

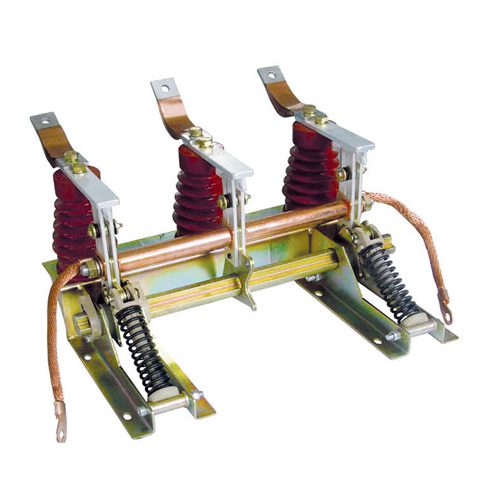

– The location of the earthing switch is generally next to the isolating switch on both sides of the circuit breaker. It plays a role in ensuring that both sides can be effectively earthed when the circuit breaker is repaired to ensure personal safety. It is not required to have a closing function and can only withstand short-circuit current, that is, dynamic thermal stability.

– The earthing on the line side mainly has the functions of closing short-circuit current and opening and closing induction current to protect the downstream equipment from damage.

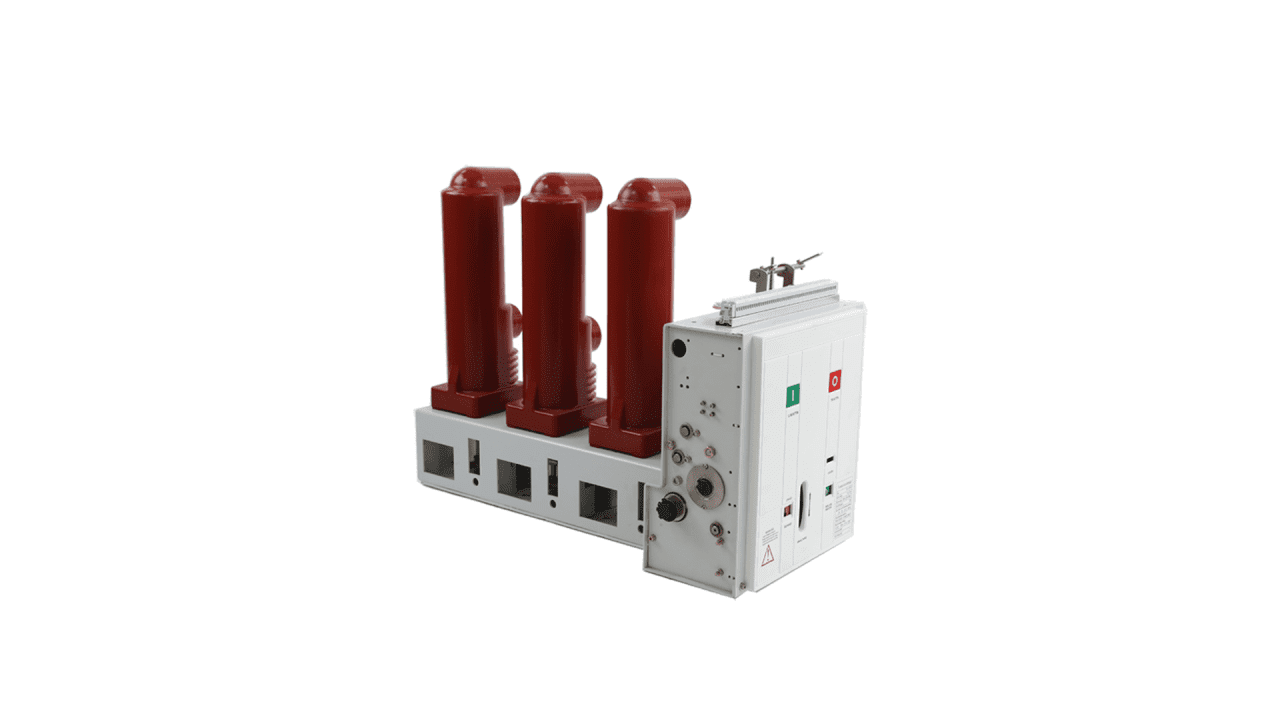

When the circuit breaker device is pointing to the test position, the earthing switch can be closed only when the line side indicates that there is no power, the live display device indicates that there is power and can operate normally, and the locking electromagnet indicates that there is power and can operate normally. If either the live display device or the locking electromagnet fails or loses power, the closing operation will not be possible. When the live display sensor fails or the line is broken, it will be reflected by the indicator light on the live display.

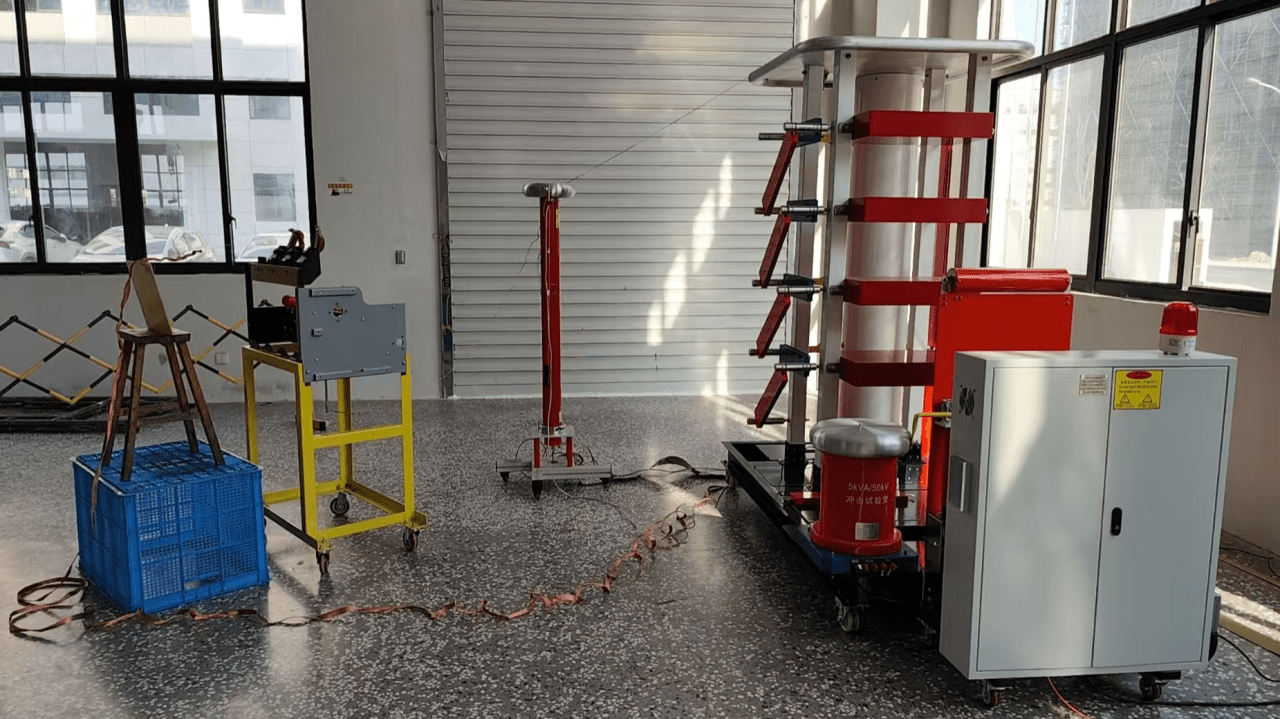

Regarding the closing of the earthing switch, many customers require E2 level 5 closings. The closing test is carried out at the rated voltage, and the closing short-circuit current is 63/80/100/130kA. The factors affecting the closing capacity are mainly:

Closing speed

If the closing speed is fast enough, the ablation of the pre-breakdown contact can be reduced, and the arcing time is short. The closing speed of the 12/24kV earthing switch in air is 4-5m/s, and only 2-3m/s in SF6. Since the insulation strength of environmentally friendly gas is close to that of air, the closing speed of the SF6 earthing switch cannot pass the closing test.

The closing speed of the 40.5kV earthing switch in the air should be increased to 6-7m/s.

Contact shape

The electric field of the circular and rod-shaped static contacts is uniform, and the shape of the moving contacts should also be good, the electric field is evenly distributed, and the electrical breakdown distance is reduced.

Contact material

Contacts with strong ablation resistance can also reduce ablation, especially for high voltage switches such as 40.5kV and above. Using copper-tungsten arc-starting contacts or copper-tungsten alloy as contact heads can also reduce ablation.

Contact pressure

Contact pressure is a key indicator for judging the ability of earthing switches to withstand thermal stability. The contact resistance is calculated based on the contact pressure to calculate the voltage drop at the contact connection, and the voltage drop is used to determine whether the contact will be welded under thermal stability. The effect of contact pressure on closing is reflected in the fact that the contact can stop quickly after closing, and will not rebound and cause ablation.

Neutralization

Closing requires high contact neutralization. Deviation and poor neutralization will cause contact burnout and serious ablation on one side, affecting the subsequent closings.

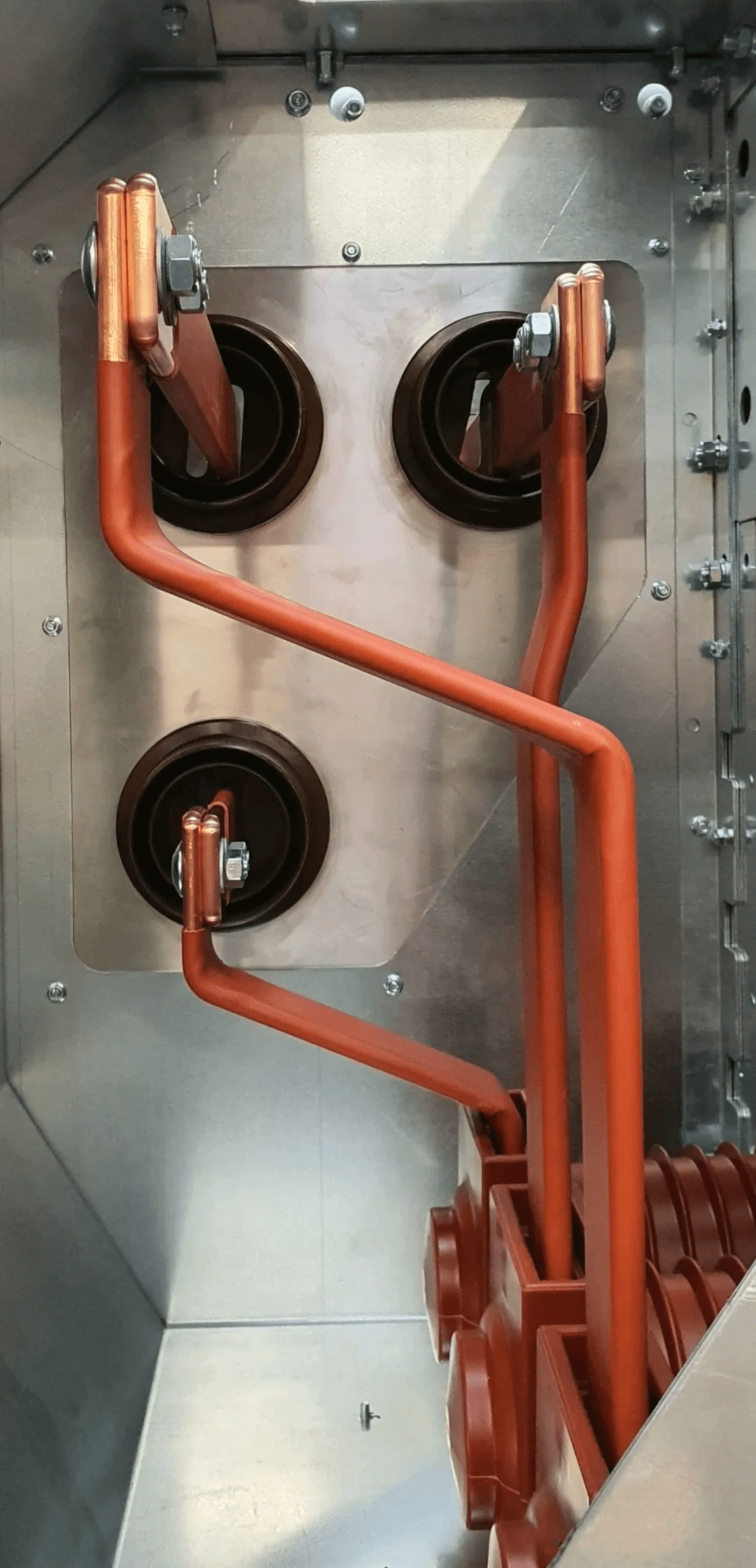

Connection arrangement

The connection arrangement involves the direction of the electric force when closing. If the direction of the electric force is conducive to closing, it will speed up the closing speed and reduce ablation. Otherwise, it will reduce the closing speed and increase the contact ablation time.

Insulating medium

Arc extinguishing performance, insulating medium directly affects the pre-breakdown distance, thus affecting the degree of ablation. SF6 gas has high insulation strength, which is only 1/3 of air, so the contact ablation of the contact is significantly smaller at the same closing speed. Because the gas gap in SF6 is small and the moving knife length is short, meanwhile the closing line speed of the SF6 earthing switch is generally smaller than that in air. So the angular velocity needs to be increased to increase the line speed.So

Conclusion

Closing speed, connection layout, and contact pressure are the main factors affecting the closing capacity.Meanwhile the contact material of the high-voltage earthing switch is also a key factor. Various factors need to complement each other. Blindly increasing the closing speed requires increasing the spring energy, which will increase the operating force, affect the life of the switch, and increase the cost. While if through reasonable design, such as connection layout, electric power to help closing, it can achieve twice the result with half the effort.