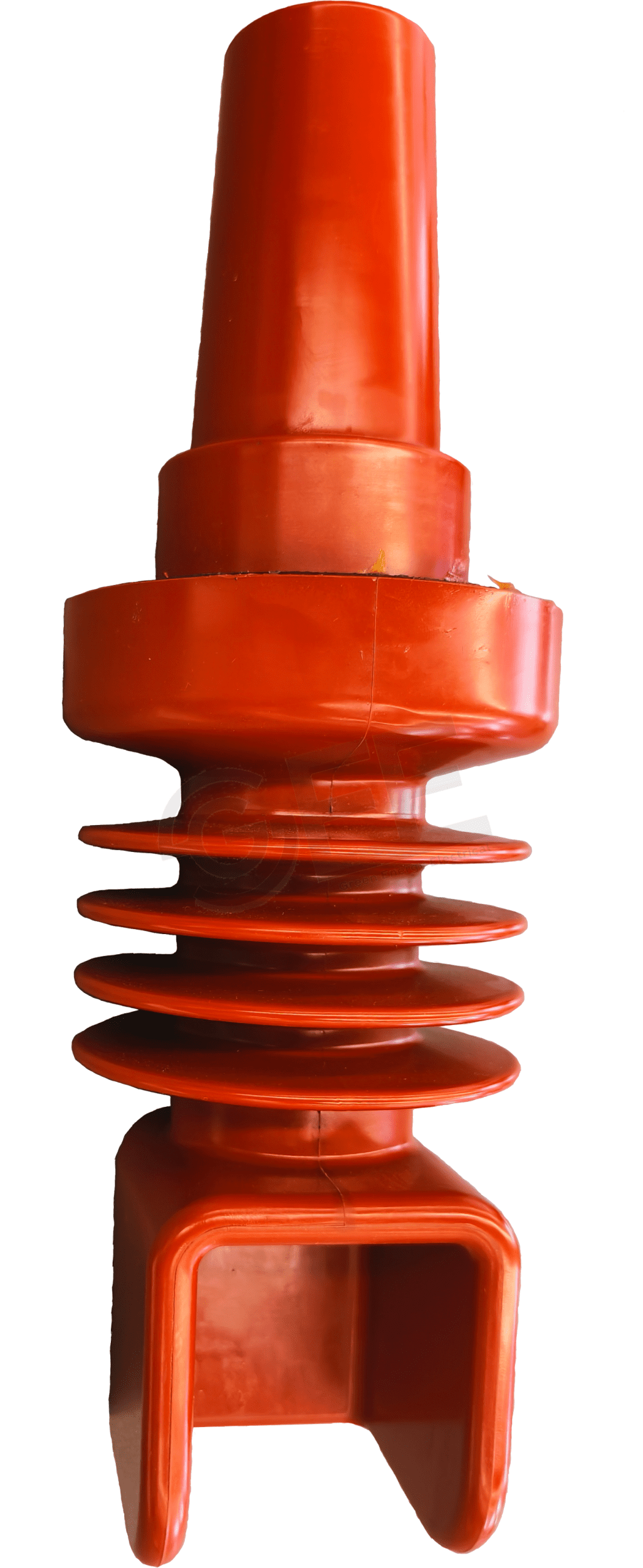

Description

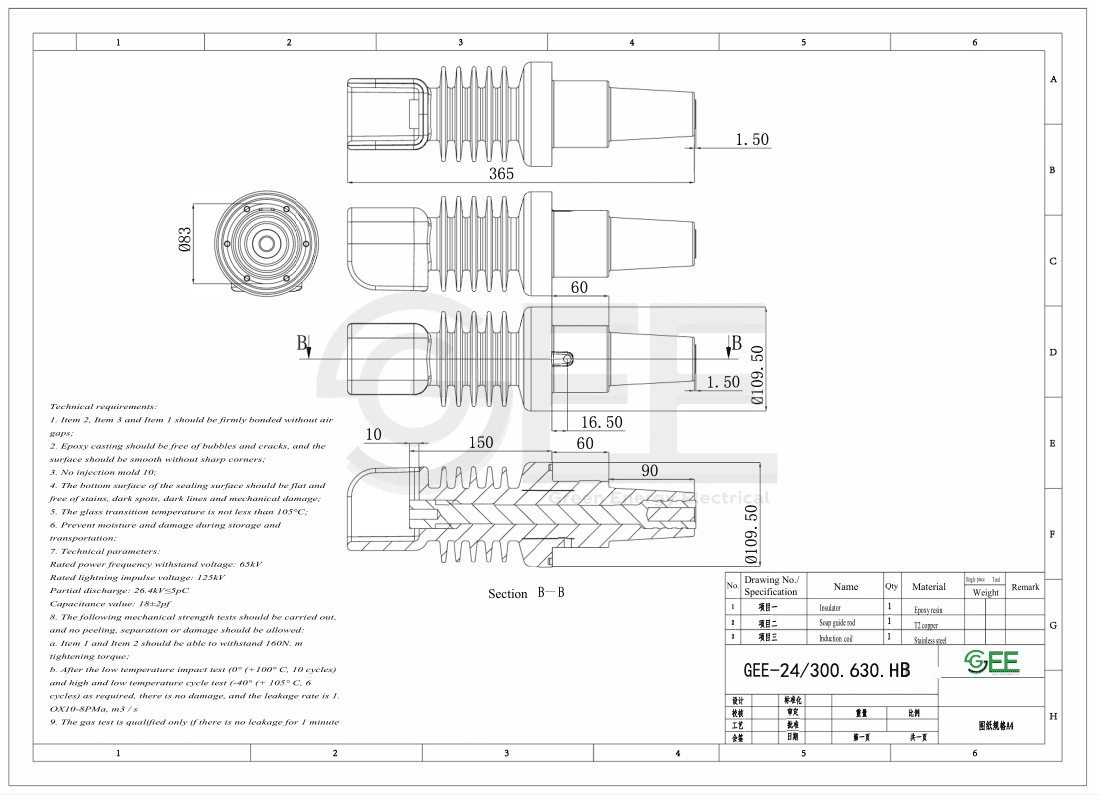

1. Item 2, Item 3 and Item 1 should be firmly bonded without air gaps;

2. Epoxy casting should be free of bubbles and cracks, and the surface should be smooth without sharp corners;

3. No injection mold 10;

4. The bottom surface of the sealing surface should be flat and free of stains, dark spots, dark lines and mechanical damage;

5. The glass transition temperature is not less than 105°C;

6. Prevent moisture and damage during storage and transportation;

7. Technical parameters:

Creepage distance is 345mm

Rated power frequency withstand voltage: 65kV

Rated lightning impulse voltage: 125kV

Partial discharge: 26.4kV≤5pC

Capacitance value: 18±2pf

8. The following mechanical strength tests should be carried out, and no peeling, separation or damage should be allowed:

a. Item 1 and Item 2 should be able to withstand 160N. m tightening torque;

b. After the low temperature impact test (0° (+100° C, 10 cycles) and high and low temperature cycle test (-40° (+ 105° C, 6 cycles) as required, there is no damage, and the leakage rate is 1. OX10-8PMa, m3 / s

9. The gas test is qualified only if there is no leakage for 1 minute