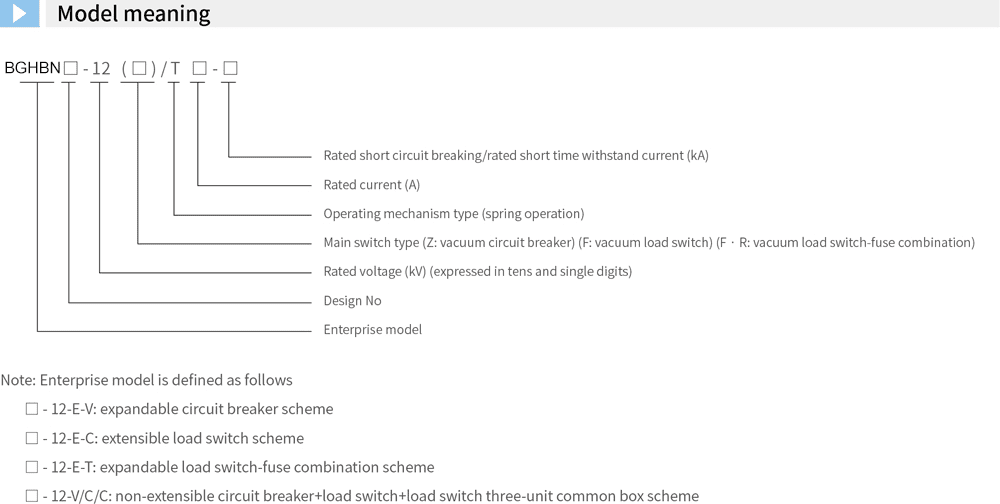

Description

Product Features

Functional composite and integrated products

The gas-filled shell of the switchgear is made of high-quality 2.5mm thick stainless steel plate by laser welding to ensure the airtightness and reliability of the gas box, high mechanical strength, and good corrosion resistance. The protection grade of the gas-filled shel reaches lP67; The air box is equipped with an explosion-proof diaphragm, which can effectively prevent damage to people and equipment caused by high air pressure; Enclosing all conductive parts in the air box can not only avoid the influence of external environmental factors, but also improve the operation reliability, make it have the function of maintenance-free or less maintenanceand also meet the requirements of volume miniaturization.

Environmental protection and pollution-free

The insulation medium of the BGHBN-12 environment-friendly gas-insulated ring-network switch is zero-grade dry air (purchased) or 99.99% pure N2 by GB/T 8979-2008. The leakage of gas will not have any impact on the external environment, and no recovery treatment is required

Perfect mechanical interlocking

The operation panel of BGHBN-12 environment-friendly gas-insulated ring-network switchgear has a complete five-prevention mechanical interlocking function. All interlocking functions have been configured internally, Please operate according to the order of the operation instructions, which is very convenient to use.

Flexible expansion design

BGHBN-12 environment-friendly gas-insulated ring-network switchgear is of modular design, which can realize diversified unit combinations through various modules through special bus connectors, and meet the complex and diverse power distribution design schemes in various parts of China to the maximum extent.

Use environment

Altitude: ≤ 2000m (installation altitude exceeds 2000m):

Ambient temperature: maximum temperature: 40 ℃ : Minimum temperature: – 40 ℃ : The average temperature within 24h shall not exceed 35℃

Ambient humidity: the average relative humidity within 24h shall not exceed 95%; The average monthly relative humidity shall not exceed 90%;

Installation environment: there is no explosive and corrosive gas in the surrounding air, and there is no severe vibration and impact in the installation site

Seismic crack degree: 8 degrees.

Basis standard

GB/T 11022-2011 Common technical requirements for high-voltage switchgear and controlgear standards

GB 3906-20063.6kV~40.5kV AC metal-enclosed switchgear andcontrolgear

GB 1984-2014 High Voltage AC Circuit Breakers

GB 3804-2004 3.6kV~ 40.5kV high-voltage AC load switch

GB 16926-2009 High-voltage AC load switch-fuse combination apparatus

GB 1985-2014 High-voltage AC disconnectors and earthing switches

GB 3309-1989 Mechanical tests of high-voltage switchgear in room temperature

DL/T404-2007 3.6kV~40.5kV AC metal-enclosed switchgear and control equipment

JB/T 3855-2008 3.6kV~40.5kV indoor AC high-voltage vacuum circuitbreaker

GB 4208-2008 Degrees of Protection Provided by Enclosures (IP Code)

GB/T 4205-2010 Human Machine Interface(MMI) – Operating Rules

GB/T 6388-1986 Shipping and Receiving MarksGB 9969-2008 General Principles of Instructions for Use of Industrial products

GB/T 13384-2008 General Technical Conditions for Packaging ofMechanical and Electrical ProductsGB/T 14436-1993 General Principles of Industrial Product AssuranceDocuments

GB/T 191-2008 Pictorial Marking of Packaging, Storage and Transportation

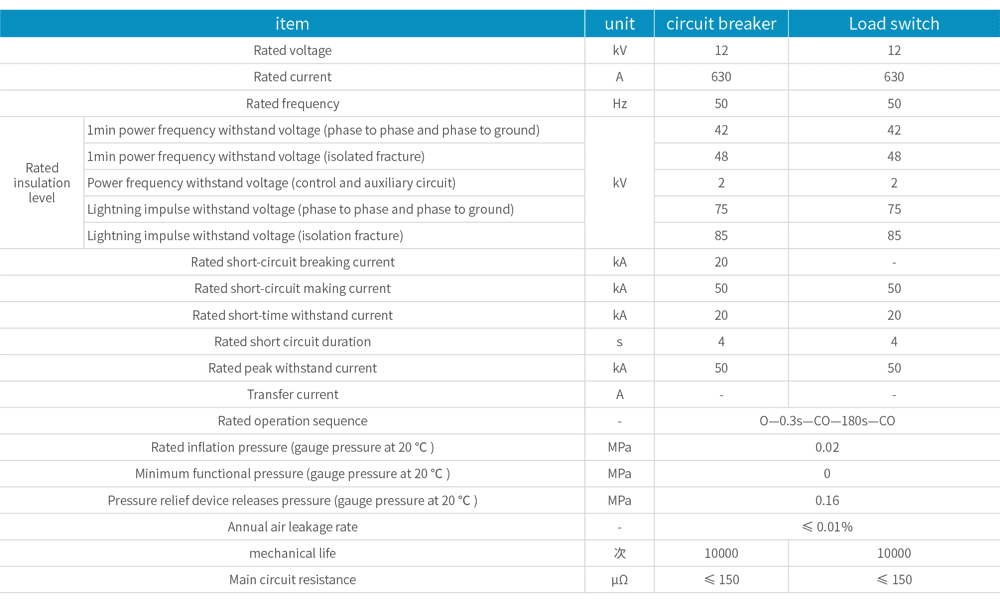

Table of Main Technical Parameters

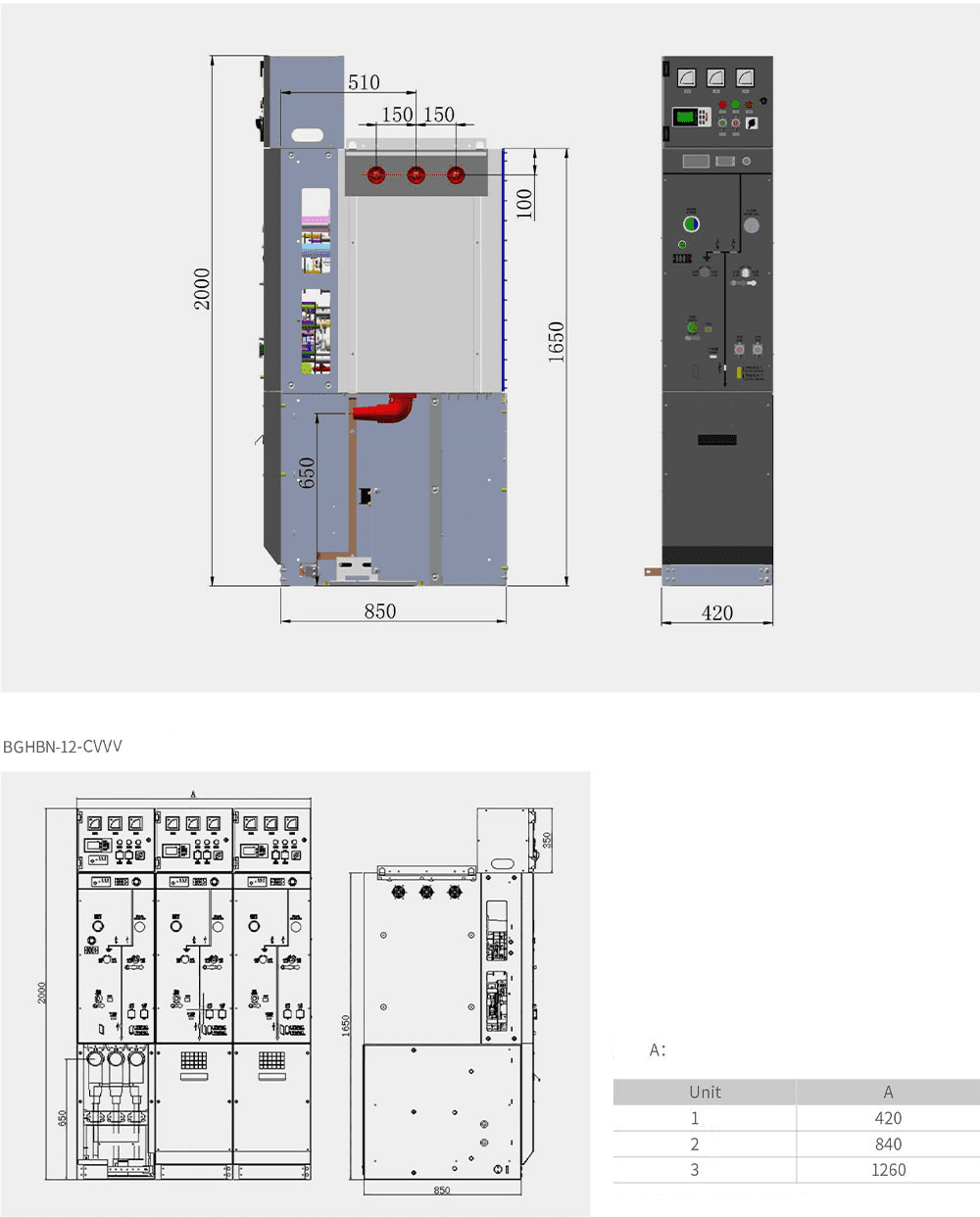

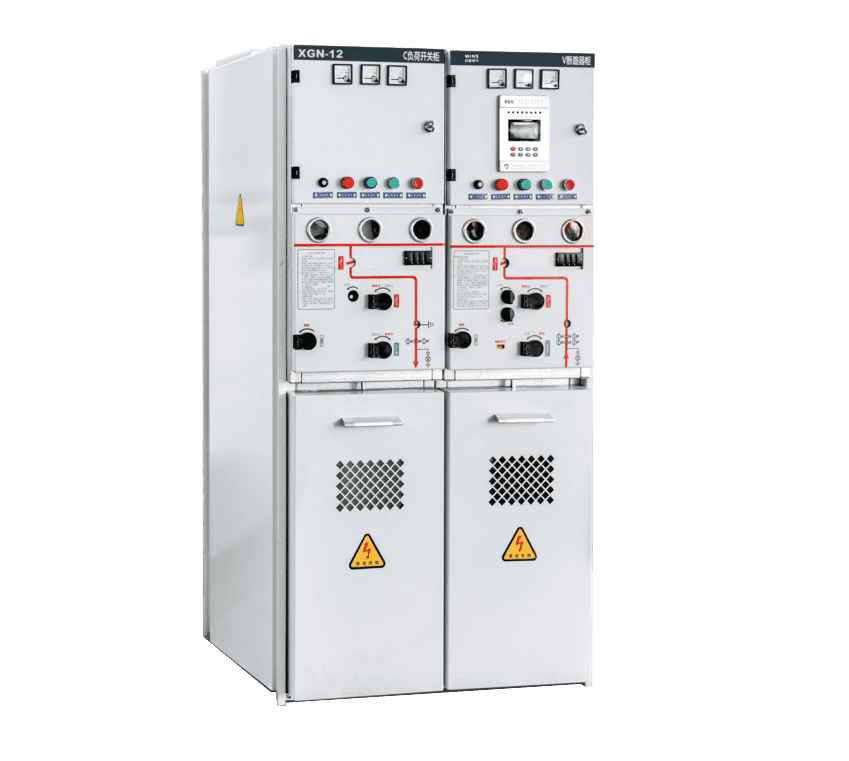

Appearance and relevant dimensions