XGNX-12(Z), XGNX-12(F), and XGNX-12(F-R) are box-type fixed metal-enclosed switchgear products. They represent a new generation of compact solutions that reduce the volume of ring network cabinet bodies by nearly 40% compared to traditional ring network cabinets consisting of vacuum circuit breakers, vacuum load switches, and combined electrical appliances. This reduction in size results in significant space savings and overall cost savings in electrical power engineering projects. These products are suitable for ring network power supply units, power plants, substations, and are especially well-suited for use in industrial and mining enterprises, residential communities, high-rise buildings, and for controlling and protecting distribution transformers. They can be installed in substations, box-type substations, open and close, and cable transfer boxes, offering versatile solutions for power distribution automation.

Description

Outlined

XGNX-12(Z), XGNX-12(F), and XGNX-12(F-R) are box-type fixed metal-enclosed RMU switchgear products. They represent a new generation of compact solutions that reduce the volume of ring network cabinet bodies by nearly 40% compared to traditional ring network cabinets consisting of vacuum circuit breakers, vacuum load switches, and combined electrical appliances. This reduction in size results in significant space savings and overall cost savings in electrical power engineering projects.

These products are suitable for ring network power supply units, power plants, substations, and are especially well-suited for use in industrial and mining enterprises, residential communities, high-rise buildings, and for controlling and protecting distribution transformers. They can be installed in substations, box-type substations, open and close, and cable transfer boxes, offering versatile solutions for power distribution automation.

Product Structure Characteristics

- Solid-Sealed Pole Structure: Vacuum circuit breakers and load switches use a three-phase solid-sealed pole structure. Vacuum interrupters and outlet terminals are encapsulated with epoxy resin materials known for their excellent insulating properties. This forms solid insulation through the Automatic Pressure Gel (APG) process. The switch structure boasts high mechanical strength and robustness, overcoming vulnerabilities related to phase-to-phase and ground-to-ground insulation, which can be affected by contaminants and dew condensation. This design also reduces the switch’s size, enhancing electrical safety.

- Integrated Three-Switch Modules: The integration of three switch modules, each featuring self-fitted disconnecting switches with clearly visible disconnecting breaks, ensures operator safety. A reliable mechanical interlock exists between the disconnecting switch and the circuit breaker (load switch) and an optional earthing switch. The disconnecting switch and the earthing switch share the same operating shaft, with the earthing switch tripping when the disconnecting switch closes. Only one of them can be in the closed state at any given time, achieving interlocking between the earthing switch and the disconnecting switch.

- Flexible Combinations: The unit assembly structure allows for flexibility. When one circuit fails, it can be replaced with a new circuit. Additionally, it accommodates various design circuit programs, such as double disconnecting switch units or double grounding switch units, meeting the user’s primary system requirements.

- Adjustable Configuration: The integrated three-switch module can be flipped up and down to meet different wiring schemes, including upper and lower incoming, outgoing, and contact configurations.

- Optimized Spring Manipulating Mechanism: The circuit breaker (load switch) features an optimized spring manipulating mechanism. It can be operated both electrically and manually with minimal operating power, ensuring high stability and reliability. The mechanism operates independently of the switches, requiring minimal adjustment and maintenance and facilitating intelligent automatic operation.

- Versatile Cabinet Structure: The cabinet structure offers strong versatility and can be configured with SF6, FKN12, FZN25, GN19, and other switches to meet various user system requirements.

Use of Environmental Conditions

- Altitude: Up to 1000 meters.

- Ambient Air Temperature: -25°C to +40°C.

- Air Relative Humidity: Daily average not exceeding 95%, monthly average not exceeding 90%.

- Environmental Conditions: No exposure to corrosive or flammable gases, water vapor, or significant pollution.

- Vibration: No regular severe vibration conditions.Note: Different environmental conditions or special requirements may necessitate consultation with the manufacturer.

Product Reference Standards

This product complies with the following reference standards:

- GB311.1-1997 “AC Power Transmission Equipment with Insulation.”

- GB1984-2003 “High-voltage AC Circuit Breaker.”

- GB3084-2004 “3-3.6kV High-voltage AC Load Switch.”

- GB16926-2009 “High-voltage Alternating Current Load Switch-Disconnector Combination Appliances.”

- GB1985-2004 “High-voltage AC Disconnecting Switch and Earthing Switch.”

- GB3309-1989 “High-voltage Switchgear Mechanical Test at Room Temperature.”

- GB11022-1999 “High-voltage Switchgear and Control Equipment Standard Shared Technical Requirements.”

- DLT403-2000 “12~40.5kV Indoor High-voltage Vacuum Circuit Breaker Ordering Technical Conditions.”

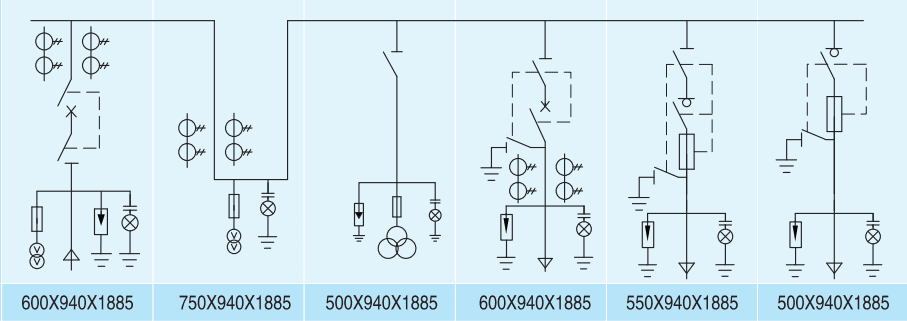

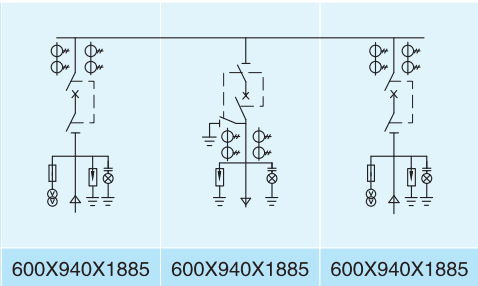

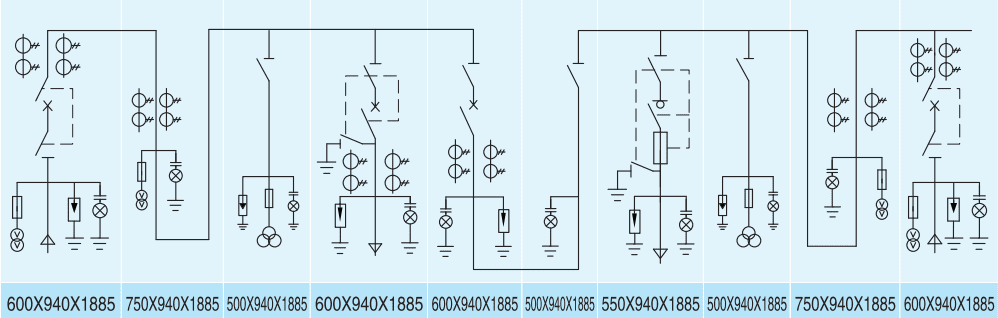

Programme and size