Transformer seepage leakage of oil specific hazards

1. transformer oil seepage phenomenon not only seriously affects the appearance, but also because the transformer needs to be shut down to eliminate the leakage and cause economic losses. If the transformer ground base on the more oil, may also become a fire hazard.

2. oil seepage will seriously interfere with the operation and maintenance personnel on the transformer oil storage cabinet sealing condition and oil level meter indication of the correctness of monitoring and judgment.

3. After the oil level is lowered due to oil leakage, the energized joints and switches may be operated without oil insulation, which may lead to breakdown, short-circuit, burnout, or even cause equipment explosion.

4. transformer oil leakage, will make the sealed transformer loss of sealing state, easy to make the oil paper insulation from the outside air, moisture invasion and insulation performance reduction, accelerate the aging of the insulation, affecting the safety of transformers, reliable operation.

5. In addition, when the oil storage cabinet top bleeder plug, casing conductive head and other parts of sealing damage, or oil storage cabinet top and its coupling pipe there are sand holes, due to the part of the higher, even if there may not appear seepage leakage of oil phenomenon, but may enter the rain, moisture, resulting in the deterioration of insulation performance, and even cause insulation breakdown, winding burnt accident.

Measures to deal with transformer oil seepage and leakage

Before dealing with oil seepage must be carefully analyzed to identify the cause of leakage and the exact leakage point. For the existence of oil contamination points, the first cleaning agent cleaning, rinse with clean water, and finally with a clean cloth repeatedly wipe, find the exact location of the leakage point.

①. The use of welding transformer oil leakage

Transformer tank upper oil leakage is found, only a small amount of oil can be discharged welding treatment; tank lower leakage is found, due to the core of the oil waste is too large and by the site conditions, can be used with oil welding treatment. Welding with oil should be carried out in the case of oil leakage is not significant, otherwise a vacuum should be used to drain the oil method to create a negative pressure after welding, the vacuum of the negative pressure should not be too high to equal internal and external pressure is appropriate, to avoid the inhalation of iron. Patch welding should be welded parts of the oil clean, preferably with alkaline water rinse and then dry; welding process should pay attention to prevent penetration and fire, welding parts must be in the oil surface below; welding using intermittent, fast welding, arc time should be controlled within 10s ~ 20s, never allow long continuous welding.

Patch welding oil leakage is more serious when the hole, can be first plugged with wire or riveted before welding; near the sealing rubber gasket or other vulnerable parts near the welding, should take cooling and protection measures.

Some users generally believe that the transformer body and accessories oil leakage, must be lifted out of the core put clean oil and then welded to deal with this method, although safe, but time-consuming and laborious, but also affect the electricity.

Some people are afraid to cause transformer oil fire caused by fire, in fact, this worry is redundant, oil combustion needs to have certain conditions, temperature and oxygen, but in the body of the transformer equipped with oil welding, oil is convection circulation when heat, will quickly lose heat, and there is no oxygen in the tank, so with oil repair leakage of the transformer is not burning. But the leakage of oil is easy to burn, burning airflow generated by the welding rod solution is difficult to fall to the cracks, resulting in welding difficulties.

So can this difficulty be solved away? The following is introduced to the transformer with oil leakage repair specific methods:

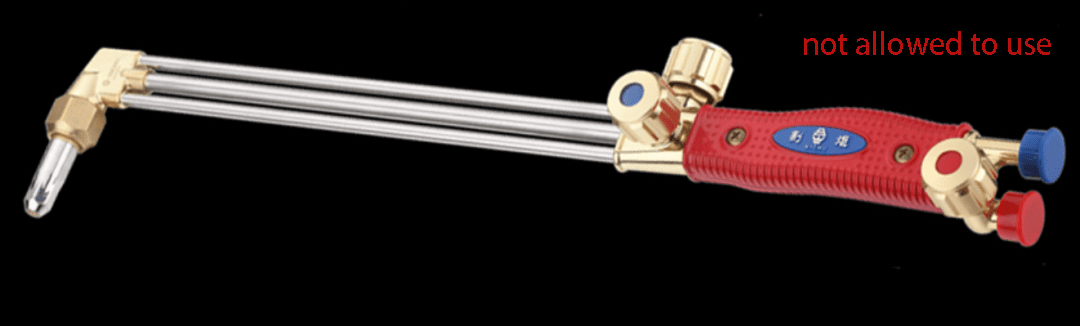

(1) according to the oil repair when the heat is quickly dispersed away from the characteristics of the use of electric arc welding for repair, do not use gas welding.

(2) In order to prevent the leakage of oil from vaporizing and hindering welding, you can use asbestos rope or other softer thin rope to plug the leakage, and then weld. For larger leaks, you can weld one part by one part, and then plug the leak with asbestos rope and weld it when the leak is reduced to one point. If it is the body leakage, you can use a hammer to twist lightly, the leakage of oil twisted to death and then welded.

(3) welding speed should be fast, for oil leakage at the larger gap, it is best to weld a moment to stop for a while, each welding time does not exceed 20 seconds. Intermittent a few minutes and then weld, let the oil cool down for a while.

(4) If the oil leakage is not obvious, just a slight oil leakage phenomenon, you can use soap to temporarily fill the leakage, the method is to use soap with water to soak, and then in the oil seepage point back and forth a few times can be coated. This method is only a temporary measure, waiting for the opportunity to weld the leak. But there is a need to pay attention to, before welding must be blackout, to confirm that there is no electricity before proceeding, and the oil pillow on the oil hole screws open, so that air circulation. At the same time, prepare sand and fire extinguishers and other firefighting equipment, just in case.

② Replacement of sealing governance transformer oil leakage

Seal rubber pressure-bearing area should be compatible with the force of the screw, otherwise it is difficult to press; replacement of the oil plug rubber sealing ring, the component should be closed at the inlet of the valves and channels, in its own negative pressure to maintain to a large number of oil out of the case of replacement, seals should have good oil resistance and anti-aging properties, better elasticity and mechanical properties, sealing materials as far as possible to avoid the use of asbestos packing and cork pads and other materials.