Our commonly used 24/40.5kV switchgear contact boxes and through-wall bushings basically use internal and external shielding forms, i.e. capacitive voltage divider bus bushings, which are bus bushings made by utilizing the principle of capacitive equipotential shielding and voltage divider to effectively reduce the size of the bushings and withstand higher lightning impulse withstand voltages and industrial frequency withstand voltages.

Sleeving or similar structures are used in medium voltage switchgear to transport conductors from one side of the grounding barrier to the other. Typical uses are roof entrance bushings, which are used to carry conductors from the outside of the switchgear through the roof to the inside of the switchgear; high-voltage disconnect outlets, which carry the high-voltage connections of the circuit breaker from the busbar or cable compartment to the circuit breaker compartment; and main bus penetrations, which are used to carry conductors from one switchgear unit to the next, and the contact box, which also belongs to the category of bushings.

In its simplest form, a bushing consists of a conductor, some surrounding insulation, and some sort of mounting device. If the voltage is not too high and the configuration of the conductor, insulation and grounding layer are not too poor, it is possible to make bushings with suitable insulation characteristics and long life using only these basic ingredients.

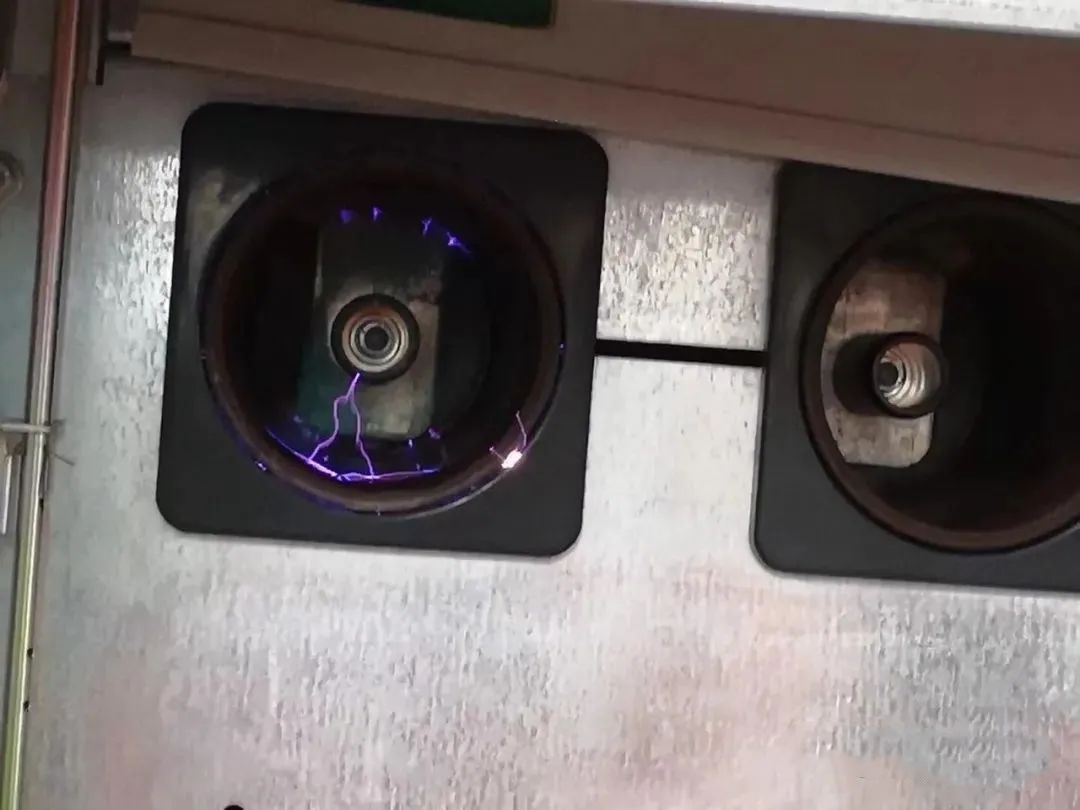

However, sometimes the spacing is very small, or the planes have sharp corners or protruding hardware, which can cause excessive localized stresses on the insulator. If the mounting holes on the mounting plate of the contact box are step-punched with a CNC punch to form a toothed tip, a breakdown discharge occurs during the frequency withstand voltage test, and even if a new product can pass the test, a breakdown will occur after a long period of operation, causing an accident.

In this case, capacitive grading casing may be the answer. In capacitance-graded bushings, layers of conductive or semi-conductive material are placed in the thickness of the insulation in such a way that these layers act as built-in capacitors and the stresses on the insulation are equalized and controlled. The correct use of capacitive grading controls the insulation and surface stresses. This technique has long been used in medium voltage switchgear. Through the inner shielding and high-voltage conductor connection, the outer shielding and cabinet grounding, the formation of capacitance in the insulating layer, can withstand high voltages, now 24kV casing, contact box, etc. has been used to equalize the voltage shielding, 40.5kV contact box casing must be shielded mesh, otherwise it is difficult to ensure the long-term safety of the operation, and is also the realization of the miniaturization of switchgear equipment must be applied to the technology.

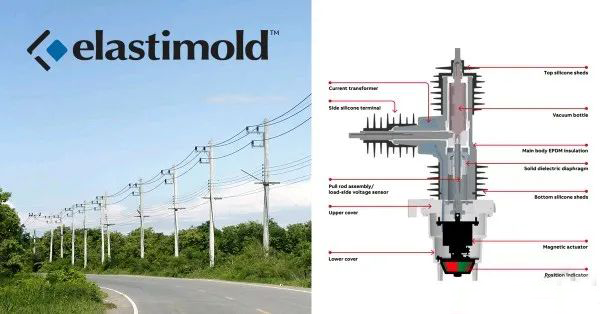

For example, the vertical lifting Magne-Blast circuit breaker of General Electric GE in the United States was first manufactured nearly 60 years ago, which uses capacitively graded top-mounted bushings to control the stress of the casing across the top frame of the circuit breaker.

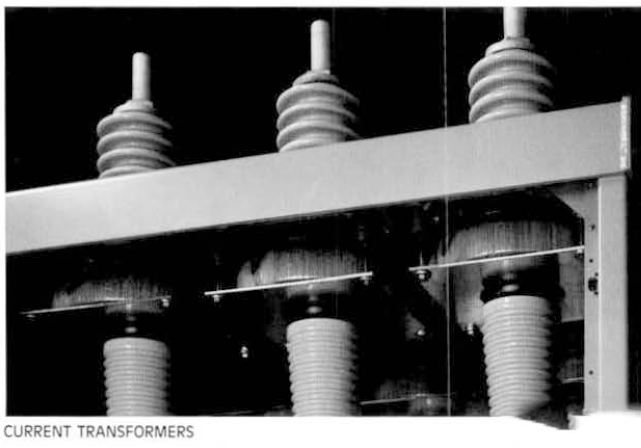

In the capacitively graded high-voltage bushing used in Powell’s PV System 38® switchgear, each line in the thickness of the insulation represents a conductive layer. The innermost layer is connected to the high voltage conductor and the outermost layer is connected to ground. In addition to controlling stresses in the insulation, this special construction provides an area around the nozzle shielded from the electric field for the installation of current transformers.

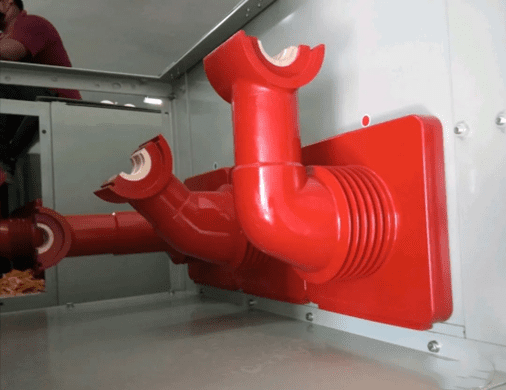

The following picture of the American Standard 38kV switchgear contact box, low-voltage penetrating current transformer installed in the front of the contact box within the handcart room, this casing can only be used to meet the insulation and small diameter requirements by using a capacitive isovolumetric shielding design, the current transformer withstand voltage of 3kV at work frequency, the impact withstand voltage of 10kV, the inner diameter is only 190mm, can not meet the requirements of the 38kV insulation withstand pressure requirements, through the grounding of shielding, to achieve the function of the requirements, meet the insulation performance, small size, easy to install.