Abstract: SF6 gas is a restricted greenhouse gas in the Kyoto Protocol. Some countries and regions have proposed control measures on the use of greenhouse gases, such as the Clean Energy Future Plan launched by Australia, and the EU has banned the use of ≤24kV primary and secondary distribution switchgear with GWP ≥10 fluorinated gases as insulating or disconnecting medium in new and expansion projects from 1 January 2026, and banned the use of ≥10 GWP fluorinated The use of GWP≥10 fluorine-containing gas as insulation or breaking medium ≥24kV, ≤52kV medium-voltage primary and secondary distribution switchgear is prohibited from January 1, 2030; our country has also put forward the goal of “double carbon” of carbon peak in 2030 and carbon neutrality in 2060, and the use of SF6 in distribution products, especially in the ring main unit, is imperative, as the ring main unit is of low voltage and small breaking current. The 12kV level using environmentally friendly gas insulation technology is more mature, 24kV ring network cabinet also need to study the technical solutions to replace SF6, the development of environmentally friendly gas ring network cabinet products.

0. Introduction:

Recently, the Equipment Department of the State Grid Corporation issued a notice on the comprehensive application of environmentally friendly distribution switchgear, in which the work objective is to reduce the amount of SF6 gas added to the grid, and in June 2023, to achieve the comprehensive application of environmentally friendly distribution switchgear in new equipment. State Grid’s “12 kV ring network cabinet (box) standardised design scheme” version 2022 in terms of equipment selection, deleting the relevant content of SF6 gas-insulated ring network cabinet. In terms of insulation medium, the insulation gas in the environmentally friendly gas-insulated ring network cabinet can be natural gas (such as nitrogen, dry air, etc., and it is prohibited to fill trace SF6 gas), synthetic gas (such as C4, C5 and their gas mixtures, etc.). China Energy Research Society also released the T/CERS0002-2018 “3.6kV ~ 40.5kV AC metal-enclosed switchgear and control equipment (environmentally friendly gas)” group standard, filled with environmentally friendly gas filled compartment, the rated filling pressure does not exceed 0.05MPa (relative pressure) when the standard applies. Environment-friendly gas environment-friendly gas refers to one or more kinds of non-toxic and harmless gas combination, should have good insulating properties and stability, in the process of mixing or processing, equipment operation, in the arc, water vapour and other factors under the action and decomposition of the transformation process, do not produce toxic and hazardous substances to people and the environment, and the greenhouse effect coefficient is not greater than CO2. such as dry air, nitrogen, etc. Dry air, nitrogen, etc. Environmentally friendly gas AC metal-enclosed switchgear refers to gas-insulated metal-enclosed switchgear whose main switching device is vacuum interrupter + three-position switch, adopts fully sealed structure, uses environmentally friendly gas as insulation and a small amount of solid insulation as support, and whose gas pressure in the inflatable compartment is not higher than the relative pressure of 0.05MPa during normal operation, and which has the rated level of insulation under the zero gauge pressure, but which is not able to be operated continuously, and whose continuity of operation is not lower than that of LSC2. Gas-insulated metal-enclosed switchgear. The local discharge value of the main components of environmentally friendly gas-AC metal-enclosed switchgear shall be less than 5pc, and when dry air is used for filling, the dry air shall be synthetic gas, and the technical requirements of nitrogen (N2) and oxygen (O2) used for the synthesis shall be in accordance with the quality requirements of GB/T 8979 high-purity nitrogen and GB/T 8982 medical oxygen, and the micro-water content and other indexes shall be in accordance with the standard requirements.

1. Requirements for environmentally friendly ring main unit

Gas insulated ring network cabinet, not affected by the environment, high reliability, convenient operation, low cost, relatively simple control and protection, through the integration of intelligent distribution terminals to form distribution automation, widely used in the secondary distribution system, by the power supply department and end-users are welcome.SF6 insulated ring network cabinet, make full use of the excellent insulation and arc extinguishing performance of SF6, the busbar system and switching unit are sealed in the Inside the air box, connected to the outside through the busbar bushing, SF6 isolated load switch, i.e., it can realise the closing and opening of the loop load current and meet the isolation requirements; load switch + fuse combination electrical appliance is applied to transformer protection, realising a very low-cost solution for transformer protection; isolation and grounding triplex switch + circuit breaker realises the function of opening and breaking of the short-circuit current, which is suitable for protection of the large-capacity transformer as well as the Remote power supply and disconnection function.

Therefore, the new environmentally friendly gas ring main unit must have the following characteristics if it is to replace the SF6 compact ring main unit:

a. Low cost, less increase in end-user equipment procurement costs;

b. Small size, compact, small and easy to install and use;

c. environmentally friendly gases, sufficiently low greenhouse effect, not destroying the ozone layer, non-toxic or sufficiently low toxicity, not easy to burn, explode, etc., do not use GWP ≥ 10 fluorine-containing gases;

d. Low pressure gas, rated relative pressure of 0.02 ~ 0.04 MPa, zero gauge pressure to meet the electrical insulation properties, to ensure the reliability of continuous operation, in accordance with the requirements of the T/CERS0002 Mission standard filling pressure does not exceed 0.05 MPa (relative pressure), higher security;

e. With primary scheme such as load switch, triplex switch + circuit breaker.

2. 12kV gas insulated ring main unit

For 12kV environmentally friendly gas-insulated ring main unit, both spare parts factories and complete sets of factories have mature solutions, i.e., adopting the scheme of isolation and grounding three-position switch + vacuum load switch (or vacuum circuit breaker), dry air or nitrogen insulation. State Grid Corporation 2022 centralised bidding procurement 12kV, environmental protection gas insulated ring network cabinet reached 1.005 billion yuan, accounting for 13.29%, of which Sichuan, Tianjin accounted for more than 62% of the total, the technology, production are more mature.

2.1 Design Theoretical Basis

As there is no effective alternative to SF6 as an arc extinguishing medium at this stage of the load switch, so the use of vacuum as a load switch arc extinguishing medium is the ideal alternative technology, the main problem to be solved is insulation, electrical clearance, creepage distance determines the design of environmentally friendly gas-insulated ring network cabinet.

The electrical clearance is determined by the insulation voltage level, altitude and pollution level in the micro-environment, insulation strength of the medium, electric field conditions and other factors.

a) The 12kV switchgear cabinet is required to withstand an industrial frequency withstand voltage of 42kV for 1 minute and a lightning surge withstand voltage of 75kV;

b) Altitude and pollution level in the micro-environment. For gas insulated switchgear, the conductive circuit is completely sealed in a pure environmentally friendly gas under micro-positive pressure, and the effect of altitude and pollution level in the micro-environment is negligible;

c) dielectric insulation strength, in a slightly uneven electric field, SF6 electric strength for dry air and nitrogen 2.5 ~ 3 times, for 12kV requirements of the impact withstand voltage 75kV, SF6 in the electrical clearance ≥ 40mm, using nitrogen or dry air, according to the standard IEC60071-1 “insulation fit – Part 1: Definitions, Principles and Rules,” the minimum air gap is 120 mm;

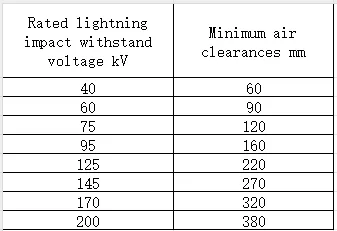

Table 1 Correlation between the rated lightning impulse withstand voltage and the minimum air gap according to IEC60071-1

d) Electric field conditions, inside the gas insulated switchgear, the electric field inhomogeneity coefficient is a key factor in determining the clear distance.

The factors of creepage distance are determined by the operating voltage level, environmental pollution level, surface quality of solid insulating materials, local electric field conditions and other factors.

a) Voltage, the creepage distance is determined on the basis of the RMS value of the long-term voltage acting across the terminals of the spanning electrodes, which is the actual operating voltage;

b) Pollution, for gas insulation regardless of environmental protection gas or SF6, because the insulating parts are completely sealed inside the gas box, not affected by the external environment, the standard definition of pollution level 1 is no pollution or only dry, non-conductive pollution, in accordance with the DL/T593-1996 “high-voltage switchgear for the common ordering of technology leading to the” indoor switchgear creepage than the distance specified in the provisions of the filth level I, organic Material 16mm/kV, so for 12kV environmentally friendly gas insulated gas box insulating parts creepage distance between the phase 192mm, 111mm to the ground that can meet the requirements;

c) solid insulating material surface quality is good or bad, insulating material resistance to leakage trace ability (CTI) that is, the material group material determines the creepage distance, high resistance to leakage trace index flame retardant reinforced nylon 66, DMC and other materials can reduce the creepage distance;

d) local electric field strength, the air gap between the insulating material and the electrode bonding will cause a concentration of local electric field, development leads to flashover along the surface.

2.2 Typical structure of 12kV environmentally friendly ring network cabinet

For 12kV environmentally friendly ring network cabinet, the main technical routes are volume increasing type, solid insulation auxiliary type, and voltage equalising and shielding type.

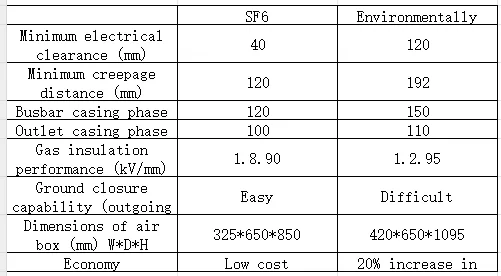

SF6 is a strong electronegative gas, the molecules have a strong ability to adsorb electrons, and the resistance to electricity is very high. Compared with SF6 gas, the breakdown field strength of environmentally friendly gas is low, and the electric strength of the air gap inside the gas chamber and along the surface of the insulating parts is much lower than that of SF6. Volume-enlarged environmentally friendly gas ring network cabinets are transformed on the basis of the circuit breaker unit of the SF6-insulated ring network cabinets, and the electric gap and creepage distance are increased to meet the requirement of 12kV lightning impact withstand voltage of 75kV. Table 2 shows the comparison between typical SF6 and environmentally friendly gas insulated ring main unit.

Table 2 Comparison of parameters between SF6 and environmentally friendly gas-insulated ring main cabinet

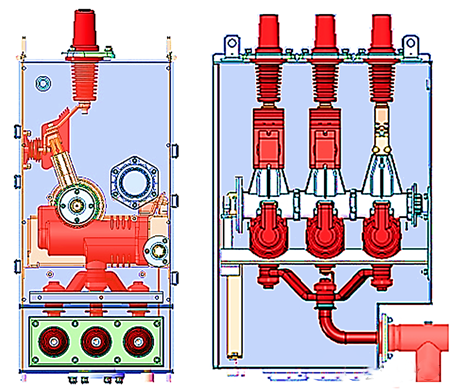

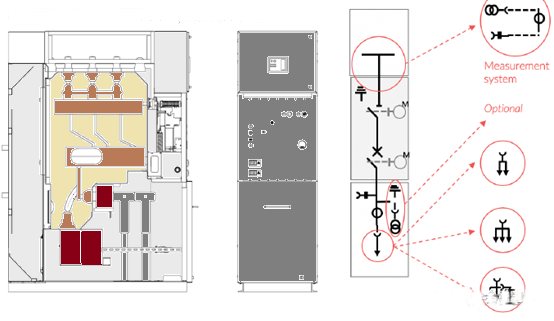

Environmental protection gas-insulated ring network cabinet without increasing the cabinet size and gas pressure conditions, the use of solid insulation as an auxiliary is an effective way, the vacuum interrupter using epoxy solid sealing, disconnecting switches using insulating cover package, busbar using epoxy resin insulation and other processing can meet the insulation requirements. Typical designs include XGN118-12 environmentally friendly gas-insulated ring network cabinet, as shown in Fig. 1, the product is based on solid insulation ring network cabinet design, a large number of epoxy resin materials are used, three-station switch + solid sealing pole load switch/circuit breaker, in addition to isolation contacts are epoxy-covered, the cost is high.

Figure 1 XGN118 type environmental protection gas ring network cabinet switching gas box unit

For the uneven electric field, and want to further reduce the size of the gas-insulated switchgear, reasonable optimisation of the conductive circuit and the shape of the electrodes, lower electric field unevenness coefficient can play a multiplier effect, can significantly improve the ability of the switchgear cabinet to withstand the impact voltage, improve the factor of safety, but also reduce the size of the material to achieve the optimisation of the cost of saving. By optimising the shape of the conductor can reduce the uneven coefficient of electric field between the air gap, reduce the air gap and solid insulation along the surface of the maximum electric field strength. The insulation structure is designed with additional voltage-averaging shielding elements to reduce the electric field strength along the high voltage side and to increase the breakdown voltage at the onset of flashover along the side. Increase the diameter of insulators and electrodes, optimize the shape of the internal inserts, the potential gradient distribution as much as possible concentrated in the solid insulation material, in order to reduce the potential gradient distribution on the surface of the insulator, increase the thickness of the insulating layer at the insulating parts such as bushings and other insulating parts grounded inserts, so that the electric field as much as possible to focus on the solid insulating material, to reduce the electric field intensity of the air-solid interface at the flange, due to the low net distance requirement inside the air box, the insulators are short. Insert height accounted for a large proportion, in this case, and then increase the umbrella skirt on the insulation is of no benefit, but instead is prone to cause the overlap region interface at the electric field strength is too large, easy to cause flashover.

2.3 Isolation break

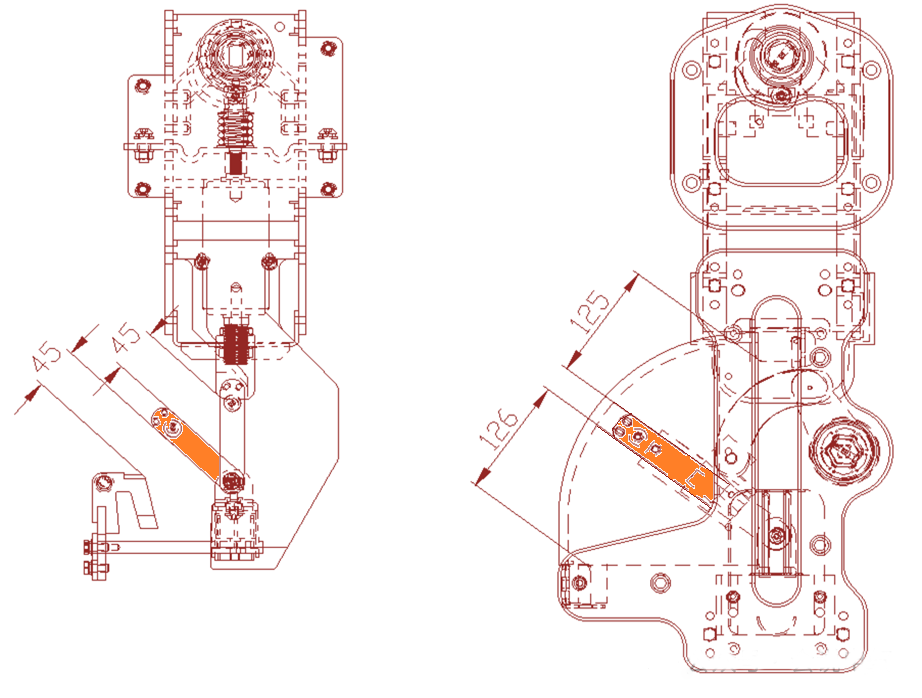

Environmental protection gas ring network cabinet through the pole solid sealing or insulation board, bus vulcanisation and other composite insulation can maintain and SF6 ring network cabinet similar to the overall size, but for the isolation of the solid insulation of the intersection can not help, as shown in Figure 2, the isolation of the intersection must ensure that the electrical distance through the intersection of the voltage requirements, in order to ensure the safety of the maintenance of the maintenance of the real. The electrical gap can be reduced by adding a voltage equalising cover to the contact area.

Figure 2 SF6 and dry air insulated disconnecting switch dimensions

2.4 Temperature rise performance

The thermal conductivity of SF6 gas is 3/4 of that of air (pure nitrogen is similar to air), and the constant pressure specific heat capacity is 0.6 times of that of air, so the heat transfer ability is worse than that of air. But the actual gas transfer process is mainly convective transfer, that is, due to the SF6 molecular weight is large, about 5 times as much as air, the molecular flow carries the heat transfer, convective transfer ability is better than air, in the filling pressure of 0.14MPa, its overall thermal conductivity is better than air (about 2 to 3 times as much as air).

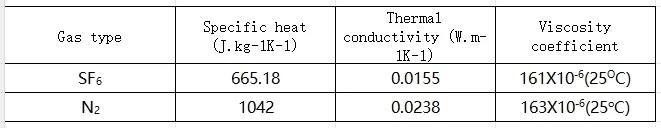

Table 3 SF6 and air thermal performance parameters

Ring network cabinet current is generally 630A, short-time withstand current 20kA, generally SF6 ring network cabinet using 6×40 rectangular bus or 18mm diameter round copper bar bus, and air-insulated switchgear 630A generally using 6×80 rectangular bus, air-insulated bus cross-sectional area of SF6 insulated ring network cabinet bus is 2 times, rectangular bus electric field is not uniform, not conducive to the insulation, so the use of 25mm diameter round copper bar bus can meet the temperature rise requirements of 630A environmentally friendly gas-insulated ring network cabinet. Therefore, 25mm diameter round copper bar busbar can meet the temperature rise requirement of 630A environmentally friendly gas-insulated ring main unit.

3. 24kV environmentally friendly gas-insulated ring main unit

Some areas of the country use 20kV voltage level, the annual procurement of 24kV ring main unit of the State Grid accounts for about 1%, if there is no 24kV is bound to affect the process of SF6, affecting the qualification of the enterprise shortlisting. Europe, Australia and other countries in the implementation of SF6 requirements, and these countries are generally used 17.5/24kV voltage level, so the early development of 24kV environmentally friendly gas-insulated ring main unit can seize the first opportunity to win the market. 24kV lightning impulse withstand voltage of 125kV, SF6 ring main unit due to the gas has a very high dielectric strength, so the general 24 kV ring main unit Dimensions and 12 kV consistent, if the use of dry air as an insulating medium, in accordance with Table 1 IEC60071 standard definition of the minimum air clearance 220mm, will inevitably need to increase the size of the ring network cabinet by a lot, so solve the insulation problem is the key.

3.1 High insulation strength environmentally friendly gas programme

24kV ring network cabinet how to achieve SF6 replacement? In accordance with GB/T11022-2020 standard non-grounding system 24kV frequency withstand voltage 65kV 1 minute, lightning impact withstand voltage peak is 125kV, significantly higher than the 12kV insulation voltage, so the environmental protection of gas-insulated ring main unit volume increases a lot to be able to meet the insulation requirements, the size of the size increase is too large is the loss of the advantages of the compact gas-insulated ring main unit. Environmentally friendly gas-insulated ring main unit needs to be miniaturised to find an alternative gas with high dielectric strength not only to meet the phase-to-phase/relative ground insulation requirements but also to solve the fracture withstand voltage requirements.

a. 3M has introduced NovecTM4710 (C4F7N), 5110 (C5F10O) synthetic gases, by mixing with CO2 or (and) O2 to become environmentally friendly gases, instead of SF6 gases environmentally friendly gas insulating medium, C4F7N and CO2 mixture of gases, of which the GWP value of C4F7N is 2090, and the insulating performance reaches more than twice the pure SF6. CO2 has excellent arc extinguishing properties and shows strong synergy with C4F7N. The GWP values of the gas mixtures containing 4% C4F7N and 6% C4F7N are 327 and 462 respectively, which is 98% less than SF6, and the insulation performance can reach about 90% of pure SF6, so it can be used as a direct gas replacement of the circuit breaker scheme without changing the size of the gas box, conductive circuit and so on, and it can satisfy the insulation requirements of the 24kV ring network cabinet.

Figure 3 Dry air insulated switchgear

Through ANSYS electric field analysis of SF6 insulated ring main unit, the weak point of insulation of 24kV ring main unit under gas mixture is clarified, and necessary insulation reinforcement is carried out for the mounting bracket and bolts of the product. As a result of strengthening the insulation, comprehensive product cost performance, the gas mixture ratio of 4% C4F7N and 96% CO2, design pressure 0.14Mpa, further ANSYS simulation analysis, the product can meet the insulation requirements. Insulation test is carried out on the product, and it passes the voltage withstand test of 65kV of industrial frequency and 125kV of lightning impact under 0.135Mpa.

The thermal conductivity of C4F7N gas mixture is about 85% of SF6 gas, and it is necessary to increase the cross-sectional area of the conductive circuit of the product to ensure that the temperature rise meets the standard requirements. By changing the copper row from 50×6 to 50×8, the product successfully passed the 1.1 times 630A temperature rise test with a large margin, changed the copper row back to the original specification and passed the test, so 10% C4F7N and 90% CO2 gas mixture has little effect on the temperature rise.

The C4F7N gas mixture was applied to the 24kV ring main unit to achieve a compact product in line with SF6 insulation without the need to increase the filling pressure, and to achieve miniaturisation compared to dry air or nitrogen insulation. Similar solutions have been adopted by foreign ring main unit manufacturers. Schoenxi USA uses the C4F7N gas mixture in ANSI 38kV 60Hz 25kA and IEC 36kV 50Hz 25kA ring main units, with the same external dimensions as the equipment using SF6 technology. A vacuum interrupter is used as the load-breaking device, and the three-position switch has a visible isolation break, as well as an arc-resistant design for added safety and a 97% reduction in the total carbon footprint. ABB uses a new environmentally friendly AirPlus gas mixture as the insulator. The AirPlus gas is based on 3M’s C5F10O (5110)-perfluoro-ketone molecule (C5-FK), which is used in order to ensure that the C5F10O is in a gaseous state, approximately 8% of C5F10O added to dry air can reduce the global warming potential of sulphur hexafluoride gas by 99.99%. UniSec ring main switch is insulated with AirPlus gas, and integrated with circuit breaker, disconnecting switch, and earthing switch functions as Hysec AirPlus switchgear. 24 kV switchgear is only 500mm wide, 24 kV-630 A-16kA 1s.

Due to increasing evidence that the toxicity of these two gases and their breakdown products during the disconnection process limits their application, the US company 3M announced on 20 December 2022 that it would withdraw from the production of perfluoro and polyfluoroalkyl substances (58 PFAS products including Novec4710 and Novec5110) by the end of 2025, and would stop using PFAS in its product range. Although 3M stopped production, it has been localised, so based on the application of 4710 etc. in medium-voltage ring network cabinets further research and testing is needed, especially in the voltage class of 24kV and above where the advantages of use are obvious, scientifically and reasonably assessing the comprehensive performance of existing environmentally friendly insulating gases such as C4F7N, C5F10O, etc., and developing the relevant equipment on the basis of clarifying the application scenarios and conditions, and at the same time, designing At the same time, design new gases and apply new technologies to promote the green and low-carbon development of power transmission and distribution equipment industry. In addition, China needs to strengthen the control of PFAS production, application and waste gas disposal in the future to avoid environmental and health hazards.

b. According to Bashin’s law, in the case of constant gas temperature, the gas gap breakdown voltage is a function of the product of gas pressure and gap distance, the higher the gas pressure the higher the insulation capacity, the conductor conducts electricity by charge, when the gas pressure is low, the rate of movement of the trace charge inside the insulator is intensified, so the degree of insulation is reduced. Increase the gas pressure can also improve the insulation capacity, such as dry air inflatable absolute pressure of 0.28MPa can also be achieved SF6 insulation level, so many foreign C-GIS manufacturers use high pressure programme, such as the German nuventura company developed nu1 gas-insulated switchgear rated voltage of 36kV, switchgear 650mm wide, 1500mm deep, 2300mm high, inflatable pressure (relative pressure) 1.8bar, minimum working pressure (relative pressure) 1.6bar, inflatable absolute pressure is equal to 0.28MPa, which can meet the rated insulation level of 70/170kV requirements, due to the insulation level of the switchgear cabinet relies more on the high inflatable pressure of the dry air, different from the high-voltage GIS aluminium casting cylinder, the medium-voltage inflatable cabinets generally Welded air box using 2.5mm thick steel plate, need to increase the thickness of the steel plate and increase the reinforcement in order to withstand the pressure, at the same time, the MV ring network cabinet needs to be maintenance-free, the potential air leakage caused by the risk of pressure reduction.

3.2 Design of 24kV ring main unit with dry air insulation

Solid insulation assisted + dry air insulation is the direction of 24kV ring main unit research and development, by balancing the relationship between insulation and compactness, the use of solid assisted insulation, you can pass the insulation test in the case of less increase in the size of the phase and ground, pole solid sealing can solve the vacuum interrupter and its connecting conductor insulation.

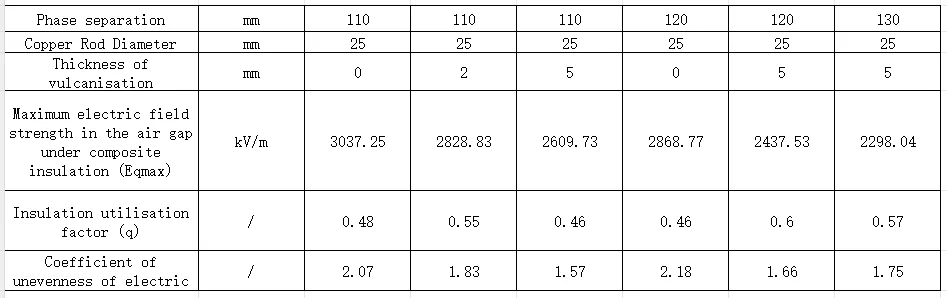

The phase spacing of the busbar at the 24kV outlet end can reduce the electric field strength and the electric field non-uniformity coefficient by sulphurising the busbar surface while keeping the phase spacing unchanged at 110mm. Table 4 calculates the different phase spacing, busbar insulation thickness of the electric field, can be seen to increase the appropriate phase spacing to 130mm, and the round bar busbar using 5mm epoxy vulcanisation treatment, this time the electric field strength of 2298kV/m, and dry air can withstand the maximum field strength of 3000kV/m there is a certain margin.

Table 4 Different phase spacing, busbar insulation thickness under the electric field situation

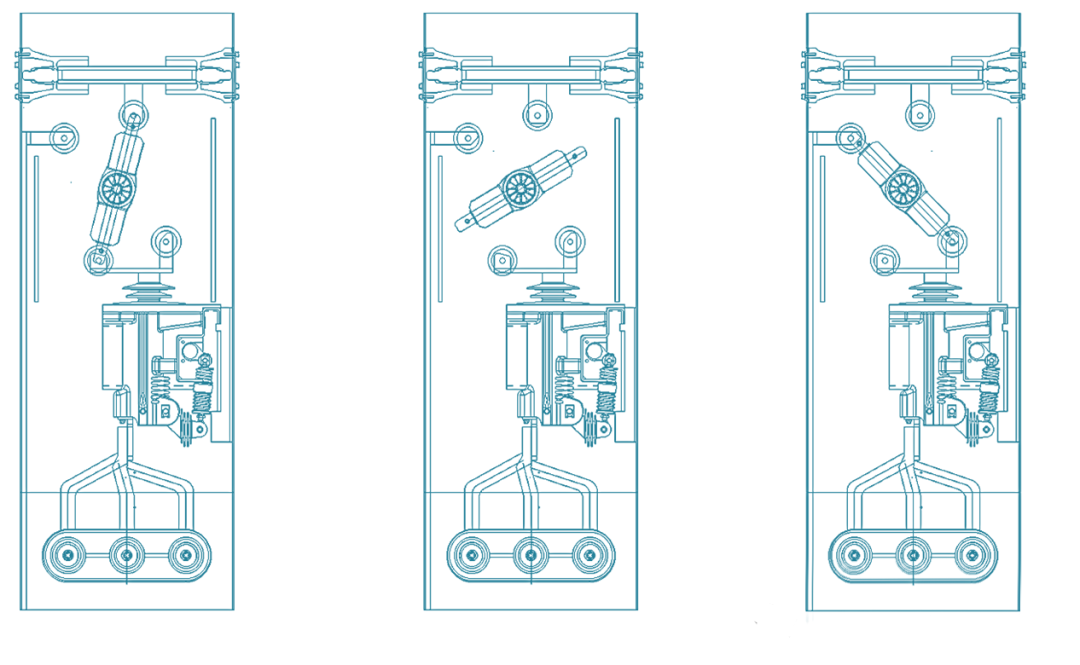

Due to the low insulation strength of dry air, solid insulation can not solve the problem of isolation fracture voltage, double isolation fracture through the two sections of the gas gap, effective voltage division, isolation, grounding static contacts and other electric field concentration of the electric field shielding design of equalisation of the pressure ring to reduce the strength of the electric field, and at the same time, effectively reduce the size of the air gap. As shown in Figure 3, the double disconnect is rotated by the reinforced nylon spindle to achieve the working state, isolation state and grounding state. The diameter of the equalising ring at the static contact is 60mm, and is treated with epoxy vulcanisation, with a clear distance of 100mm to withstand 150kV lightning impulse withstand voltage.

Figure 4 Conceptual design of 24kV environmentally friendly gas insulated ring main cabinet

Other solutions such as longitudinal split-phase arrangement, the use of high-strength single-phase alloy tanks, appropriate increase in filling pressure, etc. can also meet the 24kV withstand voltage requirements. However, the ring network cabinet needs to be low-cost, too high cost users can not accept. By optimising the design and enlarging the width of the ring network cabinet, it is possible to achieve the purpose of low cost and miniaturisation of the 24kV environmentally friendly gas insulated ring network cabinet.

4. Arrangement of earthing switches for environmentally friendly gas ring mains cabinets

There are two ways to realise the grounding function in the main circuit of the ring network cabinet: the outlet side grounding switch (lower grounding switch) or the bus side grounding switch (upper grounding switch), the bus side grounding switch can be selected as E0 class, and the main switch is required to be used in conjunction with the grounding operation. State Grid’s “Standardised Design Plan for 12kV Ring Main Cabinet (Box)” version 2022, in terms of the description of the triplex switches and the arrangement scheme, proposes that the triplex switches all adopt the busbar-side arrangement scheme and change their description to busbar-side combined function earthing switches. Electric power safety regulations stipulate that no circuit breaker or fuse shall be connected between the grounding wire, grounding knife gate and maintenance equipment. If a circuit breaker is connected between the grounding switch and the maintenance equipment due to equipment reasons, there should be measures to ensure that the circuit breaker has the ability not to be tripped after the grounding switch and the circuit breaker are closed. Therefore, the line-side earthing switch is downstream of the circuit breaker, and the earthing switch is directly connected to the outgoing cable being earthed to meet the requirement that there is no circuit breaker or fuse between the earthing line, the earthing switch and the service equipment. While the busbar side earthing switch is upstream of the circuit breaker, there is a vacuum circuit breaker between the earthing switch and the outgoing cable being earthed, which is not directly connected to the earth, and there is a circuit breaker connected between the earthing switch and the service equipment, and there should be measures to ensure that the circuit breaker will not be tripped after the earthing switch and the circuit breaker have been closed, e.g., the circuit breaker tripping circuit is broken by means of a pressure plate, or the circuit breaker is mechanically blocked from being accidentally tripped, so as to make the earthing Disconnection. The standardised design scheme of the State Grid also sets out requirements for the interlocking of the combined function earthing switch on the busbar side. When the combined function earthing switch is closed by a circuit breaker on the busbar side to achieve the function of earthing on the cable side, it should have mechanical and electrical blocking functions to prevent the circuit breaker from being manually and electrically tripped.

The standardised design scheme of the State Grid adopts bus-side isolated earthing triplex switches, which are mainly in the consideration of the earthing closing capability. SF6 is used as the insulating medium of the ring cabinet earthing switches, because the insulating strength of SF6 is three times that of the air, and the cooling effect of SF6 on the arc path is much stronger than that of the air, and its arcing capability is about 100 times that of the air, so that the earthing switch’s closing capability is guaranteed. The environmentally friendly gases do not have arc extinguishing capacity and have poor insulation capacity, so a high closing speed is required, while the ring cabinet operating mechanism has little energy and cannot provide high enough energy for closing. Therefore, the use of line-side grounding switch needs to improve the closing speed, and the contact arc resistance ability and electrodynamic analysis, which may lead to the mechanism of the operating force is large, the cost of high problems, bus-side grounding switch by solving the problem of circuit breaker blocking can also ensure the reliability of the grounding, and at the same time, the shutdown ability is stronger.

5. Conclusion

Through the SF6 and environmental protection gas technology, product analysis, it can be seen that the 12kV environmental protection gas ring network cabinet in the size of the increase is not much, that can meet the insulation, temperature rise and other requirements, the technology programme is mature. The 24kV environmentally friendly gas insulated products are not much, the key is high voltage rating, the size increases a lot, too large size, too high price will restrict the 24kV environmentally friendly gas insulated ring main unit research and development, need to balance the consideration of insulation gases, filling pressure, gas box volume, auxiliary insulation costs and other factors, design a low-cost, miniaturised ring main unit, the real realization of the SF6 substitution, can not only capture the domestic market, but also out of the country to sell! It can not only seize the domestic market, but also go out of the country and sell to all over the world to promote China’s low-carbon and environmentally friendly products.